This is the basic grade of UBE's UPILEX® polyimide.

It is characterized by extremely high rigidity and heat resistance among polyimides.

Low outgassing, excellent surface smoothness and chemical resistance.

UPILEX®

Overview

This is a super heat-resistant polyimide film with a unique composition made from BPDA (biphenyltetracarboxylic dianhydride), which is produced in-house by UBE Corporation.

It has particularly excellent dimensional stability, low water absorption, and chemical resistance.

NEW In addition to the basic grade Upilex®,

we offer a wide lineup of molded grade Upilex®-RN and functionally enhanced grades.

Features

-

1.High heat resistance

The product has normal and long-term heat resistance in the 300°C class, and is suitable for high-temperature processes up to 500°C.

-

2.High mechanical properties

Excellent toughness and abrasion resistance.

Thin films can be used for applications that require high strength. -

3.Chemical resistance

Excellent chemical resistance to organic solvents, gasoline, automotive oil, alkalis, acids, etc.

-

4.High Performance Technology

UBE's proprietary polyimide film surface layer composition is functionalized with our proprietary technology to develop even more highly functional and high-value-added films.

- #high heat resistance

- #chemical resistance

- #high dimensional stability

- #high surface smooth

- #high adhesion

- #electrical insulation

- #PI film

- #PI plastic

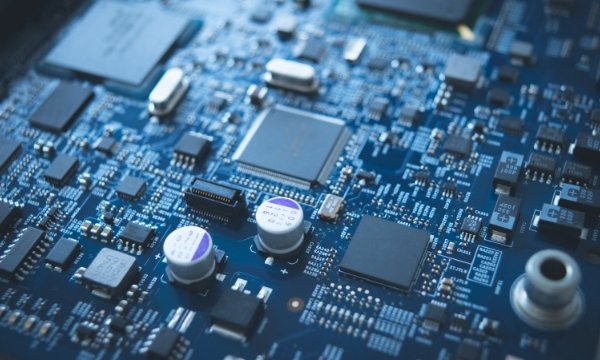

- #electronic circuit

- #thin-film sensor

- #heat-resistant resin

Applications

-

(electrical circuit) substrate

-

Thin Devices

-

Display Substrate

-

ATM Components

-

Speaker cone

Lineup

Based on the strengths of the basic grade Iupilex®-S,

we have developed a variety of film grades by utilizing our polyimide film surface functionalization technology,

which are widely used in various applications.

-

-

It has excellent physical properties such as formability and environmental resistance.

Because of its properties, it is used as an insulator, embossing, speaker diaphragm, aerospace material, and more. -

This is a thermally bondable polyimide film with a thermally bondable polyimide resin layer formed on both surfaces of a polyimide resin layer having properties equivalent to those of UPILEX®-S.

-

A polyimide film with improved adhesive properties, specially treated on both surfaces of UPLILEX®-S.