UPILEX - Ultra heat-resistant films (Grade details)

UPILEX®-S Grade

The standard grade of UBE polyimide "UPILEX®".

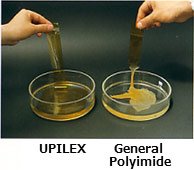

Compared to other polyimide films, it has better surface smoothness and higher chemical resistance, greater stiffness and much higher heat resistance. Outgassing is very low, so it is easy to use.

Grades and Area factor of "UPILEX®-S"

| Type | Grade | Thickness (μm) | Width* (mm) | Area factor (m2/kg) |

|---|---|---|---|---|

| UPILEX |

12.5SN | 12.5 | 508,514 | 54.4 |

| 25S | 25 | 508,514/1016,1028 | 27.2 | |

| 50S | 50 | 508,514/1016,1028 | 13.6 | |

| 75S | 75 | 508,514/1016,1028 | 9.1 | |

| 125S | 125 | 508,514 | 5.4 |

For custom widths, please contact us.

(1) Mechanical properties

"UPILEX®-S" delivers outstanding mechanical characteristics across a wide temperature range. It also demonstrates high tensile strength and modulus, and even features outstanding long-term heat resistance. Another exceptional feature of "UPILEX®-S" is its high resistance to hydrolysis, as demonstrated by its properties being virtually unaffected even when it is immersed in boiling water for long periods of time.

| Property | Unit | Standard value | Measurement Method |

|||||||

|---|---|---|---|---|---|---|---|---|---|---|

| UPILEX -25S | UPILEX -50S | UPILEX -75S | UPILEX -125S | |||||||

| -269°C | -196°C | 25°C | 300°C | 25°C | 25°C | 200°C | 25°C | |||

| Tensile strength | MPa | 740 | 650 | 520 | 290 | 460 | 360 | 270 | 340 | ASTM D882 |

| Stress at 5% elongation |

MPa | - | - | 260 | 90 | - | 210 | 110 | - | ASTM D882 |

| Elongation | % | 10 | 20 | 40 | 70 | 50 | 50 | 80 | 60 | ASTM D882 |

| Tensile modulus | GPa | - | - | 9.1 | 3.7 | 9.3 | 6.9 | 3.8 | 7.6 | ASTM D882 |

| Tear strength-initiation [Graves] |

N/mm | - | - | 600 | - | - | 470 | - | - | ASTM D1004 |

| Tear strength- propagation [Elmendorf] |

N | - | - | 3.2 | - | - | 4.2 | - | - | ASTM D1922 |

| Folding endurance [MIT] |

Cycles | - | - | >100,000 | - | - | >12,000 | - | - | ASTM D2176 |

| Density | ×103kg/㎥ | - | - | 1.47 | - | 1.47 | 1.47 | - | 1.47 | ASTM D1505 |

| Coefficient of kinetic friction (film-to-film) |

- | - | - | 0.4 | - | - | 0.4 | - | - | ASTM D1894 |

(2) Electrical properties

"UPILEX®-S" exhibits excellent electrical characteristics over a wide range of temperatures and frequencies. Even at high temperatures, "UPILEX®-S" shows almost no deterioration in its electrical properties, unlike other plastic-type films. It also displays a low level of electrical insulation defects, making it an optimal choice for electrical and electronic uses that demand high reliability.

| Property | Unit | Standard value | Measurement condition |

Measurement Method |

|||

|---|---|---|---|---|---|---|---|

| UPILEX-25S | UPILEX-75S | ||||||

| 25°C | 200°C | 25°C | 200°C | ||||

| Dielectric strength | kV | 6.8 | 6.8 | 11 | 11 | 60Hz | ASTM D149 |

| Dielectric constant | - | 3.5 | 3.3 | 3.3 | 3.2 | 1kHz | ASTM D150 |

| - | - | 3.5 | - | 1MHz | ASTM D150 | ||

| Dissipation factor | - | 0.0013 | 0.0078 | 0.0038 | 0.0056 | 1kHz | ASTM D150 |

| - | - | 0.0049 | - | 1MHz | ASTM D150 | ||

| Volume resistivity | Ω·m | >1014 | >1013 | >1014 | >1014 | DC 100V | ASTM D257 |

| Surface resistivity | Ω | >1017 | >1015 | >1016 | >1015 | DC 100V | ASTM D257 |

(3) Thermal properties

"UPILEX®-S" boasts the highest heat resistance of any plastic film currently available. Its major features include a high starting temperature for thermal decomposition, smaller values for both heat shrinkage and thermal linear expansion coefficients, as well as flame resistance (UL94 VTM-0). Therefore, "UPILEX®-S" changes little in size even when heated. This makes it ideal for use in FPC and TAB-tape substrates composed of minute circuits.

| Property | Unit | Standard value | Measurement condition |

Measurement Method |

|||

|---|---|---|---|---|---|---|---|

| UPILEX -25S | UPILEX -50S | UPILEX -75S | UPILEX -125S | ||||

| Thermal linear expansion coefficient (50-200°C) |

ppm/°C | 12 | 16 | 20 | 22 | Rise rate of temperature 5°C/min |

Fine linear dilatometer |

| Heat shrinkage | % | 0.05 | 0.02 | 0.01 | 0.01 | 200°C, 2h | ASTM D1204 |

| Melting point | °C | Non | - | - | |||

| Specific heat | kJ/(kg·K) | 1.13 | - | Differential scanningcalorimeter |

|||

| Heat life (Tensile strength) |

°C | 290 | 20,000h | Fixed temperature method |

|||

| Flammability | - | V-0 | - | UL94 | |||

| Oxygen index | % | 66 | - | JIS K7201 | |||

| Thermal conductivity |

W/(m·K) | 0.29 | Thickness direction |

Laser flash method |

|||

(4) Chemical-resistant properties

"UPILEX®-S" is insoluble in all organic solvents and is sufficiently resistant to virtually all chemicals, including inorganic acid and alkali solutions. This chemical resistance provides exceptional physical properties as well as superior dimensional stability when "UPILEX®-S" is exposed to chemicals. As resistance to various automotive oils (engine oil, brake oil, gasoline, etc.) is strong, it is suitable for use in many automotive applications.

| Property | Standard value (UPILEX-25S) | Measurement condition |

Measurement Method |

||||

|---|---|---|---|---|---|---|---|

| Strength retention (%) | Elongation retention (%) | Modulus retention (%) | |||||

| Chemical resistance | 10% sodium hydroxide | 80 | 60 | 95 | 25°C5days Immersion | ASTM D882 | |

| Glacial acetic acid | 100 | 95 | 100 | 110°C 5weeks Immersion | |||

| Water | PH=1.0 | 95 | 85 | 100 | 100°C 2weeks Immersion | ||

| PH=4.2 | 95 | 85 | 100 | 100°C 2weeks Immersion | |||

| PH=8.9 | 95 | 85 | 100 | 100°C 2weeks Immersion | |||

| PH=10.0 | 95 | 85 | 100 | 100°C 4days Immersion | |||

| Water absorption | 1.4% | 23°C 24h Water Immersion | ASTM D570 | ||||

| 0.8% | 50°C RH60% Equilibrium | ||||||

| Gas permeability | Water vapor | 1.7×10-3kg/m2/25μm | 38°C, RH90%, 24h | ASTM E96 | |||

| Oxygen | 0.8×10-6㎥/m2/25μm | 30°C, 1atm 24h | ASTM D1434 | ||||

| Carbon dioxide | 1.2×10-6㎥/m2/25μm | 30°C, 1atm 24h | ASTM D1434 | ||||

(5) Comparison of film properties

| Property | Unit | UPILEX -25S |

General Polyimide |

Polyester | Polysulfone | Polytetra fluoroethylene | |

|---|---|---|---|---|---|---|---|

| Density | ×103kg/㎥ | 1.47 | 1.42 | 1.38-1.41 | 1.24-1.25 | 2.1-2.2 | |

| Tensile strength | MPa | 520 | 170 | 140~250 | 60~70 | 10~30 | |

| Elongation | % | 40 | 70 | 60~170 | 60~110 | 100~400 | |

| Tensile modulus | GPa | 9.1 | 3.0 | - | - | - | |

| Tear strength-propagation [Elmendorf] |

N | 3.2 | 3.1 | 4.9~10.8 | 3.9~4.9 | 3.9 | |

| Chemical resistance |

Organic solvents |

- | Excellent | Excellent | Excellent | Excellent | Excellent |

| Strong acids |

- | Good | Good | Good | Excellent | Excellent | |

| Strong alkalis |

- | Good | Poor | Good | Excellent | Excellent | |

| Dielectric constant | - | 3.5 | 3.5 | 3.2 | 3.1 | 2.1 | |

| Dissipation factor | - | 0.0013 | 0.003 | 0.005 | 0.0008 | 0.0002 | |

Modern Plastics Encyclopedia; McGraw-Hill, Inc., New York

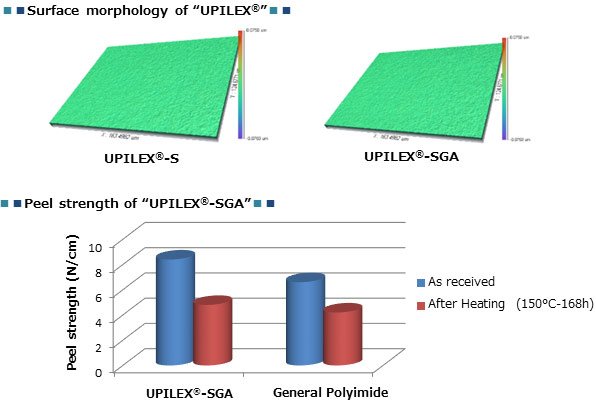

(6) Smooth surface

"UPILEX®-S" has a excellent smooth surface with low roughness. Therefore, it can also be suitably used as a film carrier base for other high heat resistance resins, cushioning materials or releasing materials.

| Surface Roughness |

Unit | Standard value | General Polyimide | PET | Measurement Method |

|||

|---|---|---|---|---|---|---|---|---|

| UPILEX -25S |

UPILEX -50S |

UPILEX -75S |

UPILEX -125S |

|||||

| Rms | nm | 3.8 | 2.0 | 2.2 | 2.1 | 5.6 | - | Scanning probe microscope (Scan area = 10mm x 10mm) |

| Ra | nm | 2.1 | 1.2 | 1.3 | 1.1 | 3.2 | 22 | |

| Rz | nm | 64.9 | 60.3 | 57.8 | 51.5 | 100 | - | |

< Carrier base, Releasing material Application Examples >

Since outgassing is very low compared to general polyimide, it is the perfect film for many applications with vacuum and/or high-temperature processing. And, resin coats formed from a carrier base of "UPILEX®-S" have moderate adhesion strength to peel off later and offer a very smooth surface.

| Coated/Laminated Resin | 180° Peel Strength (N/10mm) |

Sample preparation (Carrier=UPILEX-25S) |

|

|---|---|---|---|

| Grade | Thickness (μm) | ||

| Nitto Denko 31B | 34 | 3.0 | Laminate 31B and UPILEX-S at room temperature |

| 34 | 5.2 | Laminate 31B and UPILEX-S at room temperature And leave it for 20h at 70°C |

|

| Nichiban LP24 | 42 | 2.1 | Laminate LP24 and UPILEX-S at room temperature |

| 42 | 3.8 | Laminate LP24 and UPILEX-S at room temperature And leave it for 20h at 70°C |

|

| Epoxy Resin | 38 | 1.21) | Coating Epoxy resin on UPILEX-S and curing 1) peel off at an angle of 90° |

| Epoxy Prepreg | 91 | 1.0 | Laminate epoxy prepreg and UPILEX-S |

| UPILEX |

25 | 0.08 | UPILEX |

| UPIA |

26 | 1.1 | Coating UPIA ST(U-Varnish-S) on UPILEX-S |

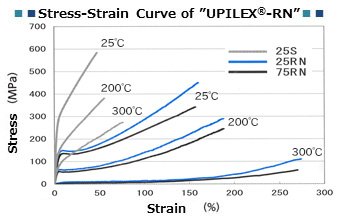

UPILEX®-RN Grade

"UPILEX®-RN" has many excellent physical characteristics, including molding process-ability and environmental resistance. Therefore "UPILEX®-RN" can be used in embossing, speaker diaphragms, aerospace applications, etc..

- "UPILEX®-RN" has excellent tolerance not only to acids and organic solvents, but also to alkalis.

- "UPILEX®-RN" has excellent heat resistance ,electrical properties, and radiation resistance.

- Since it has excellent elongation through heating and pressing, it is easy to make solid components using drawing process. Molded articles have excellent strength characteristics.

- "UPILEX®-RN" can form an excellent insulating layer by ribbon winding to a conductor such as a coil , due to it's low modulus and high flexibility compared to "UPILEX®-S".

| Type | Grade | Thickness (μm) | Width* (mm) | Area factor (m2/kg) |

|---|---|---|---|---|

| UPILEX |

25RN | 25 | 508 | 28.8 |

| 50RN | 50 | 508 | 14.4 | |

| 75RN | 75 | 508 | 9.6 | |

| 125RN | 125 | 508 | 5.8 |

For custom widths, please contact us.

(1) Mechanical properties

| Property | Unit | Standard value | Measurement Method |

|

|---|---|---|---|---|

| UPILEX-25RN | UPILEX-75RN | |||

| Tensile strength | MPa | 390 | 380 | ASTM D882 |

| Elongation | % | 160 | 150 | ASTM D882 |

| Tensile modulus | GPa | 3.9 | 3.9 | ASTM D882 |

| Density | ×103kg/㎥ | 1.39 | 1.39 | ASTM D-1505-03 |

(2) Electrical properties

| Property | Unit | Standard value | Measurement condition |

Measurement Method |

|

|---|---|---|---|---|---|

| UPILEX-25RN | UPILEX-75RN | ||||

| Dielectric strength |

kV | 7.1 | 13.9 | 60Hz | ASTM D149 |

| Dielectric constant |

- | 3.4 | 3.5 | 1MHz | ASTM D150 |

| Dissipation factor |

- | 0.007 | 0.009 | 1MHz | ASTM D150 |

| Volume resistivity |

Ω·m | >1014 | >1014 | DC 100V | ASTM D257 |

| Surface resistivity |

Ω | >1015 | >1016 | DC 100V | ASTM D257 |

(3) Thermal properties

| Property | Unit | Standard value | Measurement condition |

Measurement Method |

|

|---|---|---|---|---|---|

| UPILEX -25RN |

UPILEX -75RN |

||||

| Heat life (Tensile strength) |

°C | 270 | 270 | 20,000h | Fixed temperature method |

| Flammability | - | V-0 | V-0 | - | UL94 |

(4) Chemical property

| Property | Unit | Standard value | Measurement Method |

|

|---|---|---|---|---|

| UPILEX-25RN | UPILEX-75RN | |||

| Water absorption | % | 1.4 | 1.7 | ASTM D570 |

UPILEX®-VT and UPILEX®-NVT Grade

"UPILEX®-VT" and "UPILEX®-NVT" are heat bonding polyimide films having heat fusing layers on both side of the film, created by the polyimide resin equivalent of "UPILEX®-S". High quality flexible circuits without an adhesive layer are obtained, by heating and pressing "UPILEX®-VT" or "UPILEX®-NVT" with metal (Cu, SUS, Al) foil. In addition, they are also available for bonding films comprised of metal, ceramic and other materials.

- Flexible circuits without adhesive are produced.

- This offers high tensile strength and tear strength.

- Offering the same low water absorption, low dimensional change and high heat resistance as "UPILEX®-S", with the addition of laminate workability in the heat press.

| Type | Grade | Thickness (μm) | Width* (mm) | Area factor (m2/kg) |

|---|---|---|---|---|

| UPILEX |

12.5VT | 13 | 510, 520 | 54.9 |

| 20VT | 20 | 510, 520 | 35.1 | |

| 25VT | 25 | 510, 520 | 28.0 | |

| 50VT | 50 | 510, 520 | 13.9 |

| Type | Grade | Thickness (μm) | Width* (mm) | Area factor (m2/kg) |

|---|---|---|---|---|

| UPILEX |

12.5NVT | 13 | 510, 520 | 55.1 |

| 20NVT | 20 | 510, 520 | 35.5 | |

| 25NVT | 25 | 510, 520 | 28.4 | |

| 50NVT | 50 | 510, 520 | 14.0 |

For custom widths, please contact us.

(1) Mechanical properties

| Property | Unit | Standard value | Measurement Method |

|

|---|---|---|---|---|

| UPILEX-25VT | UPILEX-50VT | |||

| Tensile strength |

MPa | 530 | 540 | ASTM D882 |

| Tear strength |

N/mm | 3.0 | 4.3 | IPC-TM-650 2.4.17.1 |

| Elongation | % | 90 | 90 | ASTM D882 |

| Tensile modulus |

GPa | 7.5 | 7.6 | ASTM D882 |

| Density | ×103kg/㎥ | 1.43 | 1.44 | ASTM D-1505-03 |

(2) Electrical properties

| Property | Unit | Standard value | Measurement condition |

Measurement Method |

|

|---|---|---|---|---|---|

| UPILEX-25VT | UPILEX-50VT | ||||

| Dielectric strength |

kV | 7.2 | 10.5 | 60Hz | ASTM D149 |

| Dielectric constant |

- | 3.2 | 3.3 | 1GHz | Triplate-Line Resonator |

| 3.2 | 3.3 | 10GHz | Triplate-Line Resonator | ||

| Dissipation factor |

- | 0.005 | 0.004 | 1GHz | Triplate-Line Resonator |

| 0.007 | 0.007 | 10GHz | Triplate-Line Resonator | ||

| Volume resistivity |

Ω·m | >1014 | >1014 | DC 100V | ASTM D257 |

| Surface resistivity |

Ω | >1015 | >1015 | DC 100V | ASTM D257 |

(3) Thermal properties

| Property | Unit | Standard value | Measurement condition |

Measurement Method |

|

|---|---|---|---|---|---|

| UPILEX -25VT |

UPILEX -50VT |

||||

| Thermal linear expansion coefficient (50-300°C) | ppm/°C | 20 | 20 | - | Fine linear dilatometer |

| Heat shrinkage | % | 0.31 | 0.35 | 300°C, 2h | JIS C2318 |

| Thermal decomposition temp. at 5% weight loss |

°C | 584 | 582 | In Air | TG-DTA |

| Flammability | - | V-0 | V-0 | - | UL94 |

(4) Chemical properties

| Property | Unit | Standard value | Measurement Method |

|

|---|---|---|---|---|

| UPILEX-25VT | UPILEX-50VT | |||

| Water absorption | % | 1.1 | 1.4 | ASTM D570 |

| Moisture Absorption | ppm/%RH | 14 | 13 | UBE method |

UPILEX®-SGA Grade

"UPILEX®-SGA" is a polyimide film having improved adhesion properties created by a special process to both sides of the "UPILEX®-S".

It is suitable for sputtering or plating processes because of high surface adhesion. It offers a flexible base for high-performance electronic circuits.

In addition, it can also be used as an adhesive tape base material for LOC packaging.

- In sputtering or plating, a flexible base for electronic circuits that does not use any adhesives can be obtained.

- Peel strength is high, surface smoothness is very high.

- Superior mechanical property, with low water absorption, excellent dimensional stability and high heat resistance comparable to "UPILEX®-S".

| Type | Grade | Thickness (μm) | Width* (mm) | Area factor (m2/kg) |

|---|---|---|---|---|

| UPILEX |

25SGA | 25 | 508 | 27.2 |

| 50SGA | 50 | 508 | 13.6 |

For custom widths, please contact us.

(1) Mechanical properties

| Property | Unit | Standard value | Measurement Method |

|

|---|---|---|---|---|

| UPILEX -25SGA |

UPILEX -50SGA |

|||

| Tensile strength | MPa | 490 | 490 | ASTM D882 |

| Elongation | % | 40 | 45 | ASTM D882 |

| Tensile modulus | GPa | 10.0 | 9.7 | ASTM D882 |

| Density | ×103kg/㎥ | 1.47 | 1.47 | ASTM D-1505 |

(2) Electrical properties

| Property | Unit | Standard value | Measurement condition |

Measurement Method |

|

|---|---|---|---|---|---|

| UPILEX -25SGA |

UPILEX -50SGA |

||||

| Dielectric strength |

kV | 6.4 | 10.6 | 60Hz | ASTM D149 |

| Dielectric constant |

- | 3.4 | - | 1GHz | IPC-TM650 2.5.5.9 |

| Dissipation factor |

- | 0.003 | - | 1GHz | IPC-TM650 2.5.5.9 |

| Volume resistivity |

Ω·m | >1014 | >1014 | DC 100V | ASTM D257 |

| Surface resistivity |

Ω | >1016 | >1016 | DC 100V | ASTM D257 |

(3) Thermal properties

| Property | Unit | Standard value | Measurement condition |

Measurement Method |

|

|---|---|---|---|---|---|

| UPILEX -25SGA |

UPILEX -50SGA |

||||

| Thermal linear expansion coefficient (50-200°C) | ppm/°C | 13 | 14 | - | Fine linear dilatometer |

| Heat shrinkage | % | 0.06 | 0.06 | 200°C, 2h | ASTM D1204 |

(4) Chemical property

| Property | Unit | Standard value | Measurement Method |

|

|---|---|---|---|---|

| UPILEX -25SGA |

UPILEX -50SGA |

|||

| Water absorption | % | 1.2 | 1.4 | ASTM D570 |