| Item | Unit |

UIP-R Shape |

UIP-S Shape |

UIP-SA Shape |

Measurement Method |

|---|---|---|---|---|---|

| Specific gravity | - | 1.39 | 1.47 | 1.48 | ASTM D-792 |

| Water absorption | % | 0.46 (48 hr) |

0.12 (48 hr) |

0.03 (24 hr) |

ASTM D-570 |

| Tensile strength | MPa | 120 | 80 | 110 | ASTM D-638 |

| Elongation | % | 5 | 2 | 4 | ASTM D-638 |

| Flexural strength | MPa | 160 | 100 | 140 | ASTM D-790 |

| Flexural modulus | GPa | 4.2 | 8.0 | 7.5 | ASTM D-790 |

| Izod Impact (notched) |

J/m | 75 | 22 | 20 | ASTM D-256 |

| Rockwell hardness | M scale | 114 | 113 | 115 | ASTM D-785 |

| Heat distortion temp. (1.82 MPa) |

°C | 360 | 500 | 470 | ASTM D-648 |

| Coefficient of thermal expansion |

ppm/°C | 55 (20-250°C) |

37 (20-250°C) |

35 (25-450°C) |

ASTM D-233 |

| Tabar abrasion loss | mg/1000 cycle | 15 | - | 20 | ASTM D-1044 |

| Limiting PV value | MPa·m/sec | 1.7 | 2.2 | - | S45C,0.5m/s |

Position and Features

Features Polyimide shape from UIP

- Super high heat resistance

- Low outgas

- Good processability

- Low particles

Heat Distortion Temperature vs Flexural Modulus

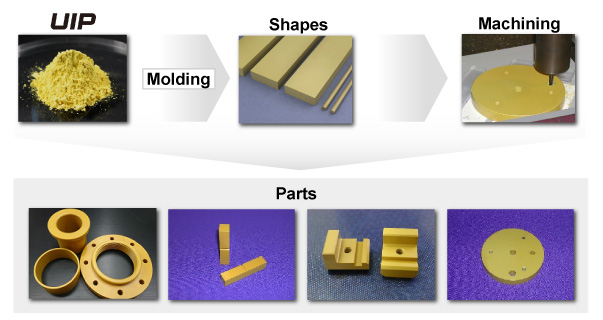

Process Flow of UIP Shapes

UIP can make you to lead into wide spreaded various application field

Application Example

Electronics

- Micro-switch

- Guide piece

- Bearing

- Center pin

- Vacuum pad

Automotive

- Friction pad

- Valve seat

- Bushing

- Trust washer

- Bearing retainer

Machine

- Bearing sleeve

- Roller bushing

- Vane

- Piston ring

Aerospace

- Seal ring

- Piston ring

- Gear

- Locknut insert