Ube Research & Development Center

Organization Overview

(Polyimide Group, Specialty Products Processing Group, Membrane Group, Electronic Materials Group)

Our department is engaged in the development of new products and new production technologies to drive the growth of specialty chemicals.

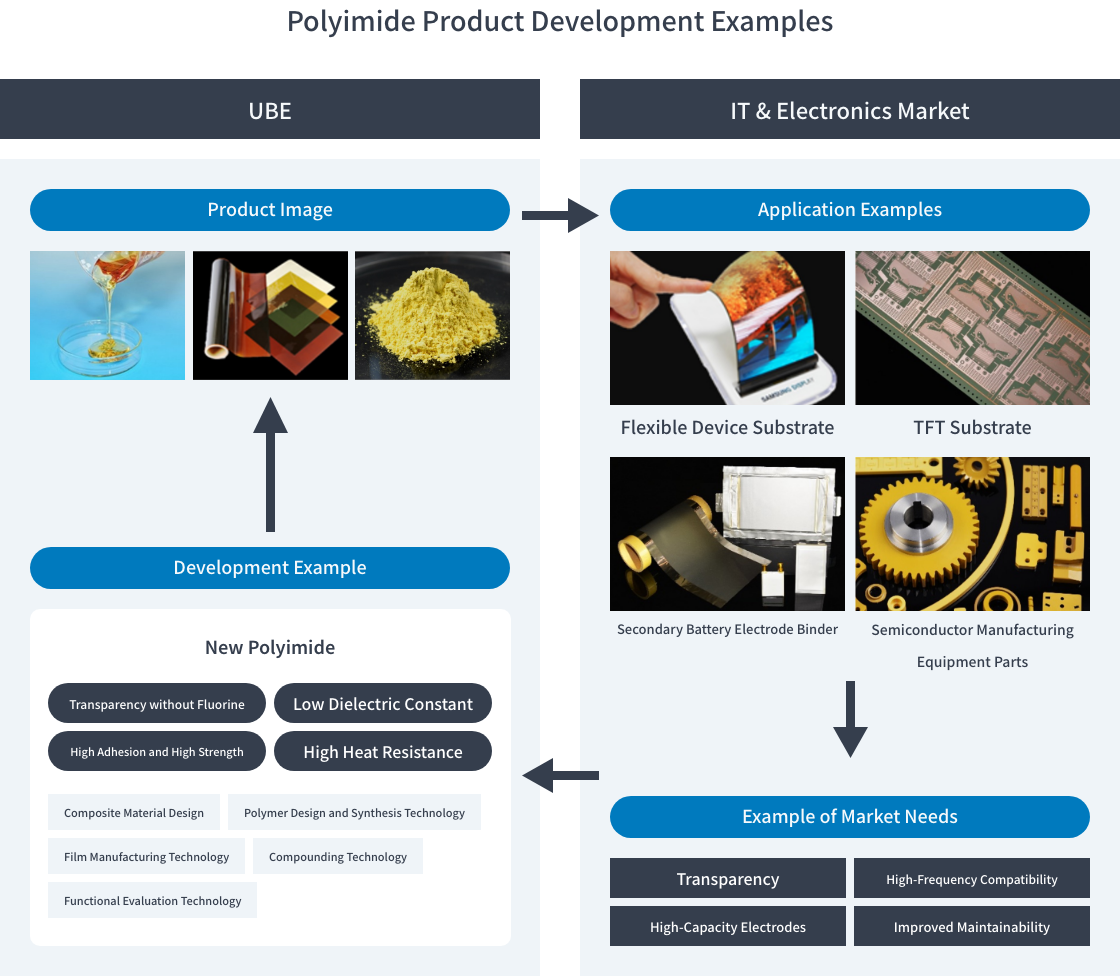

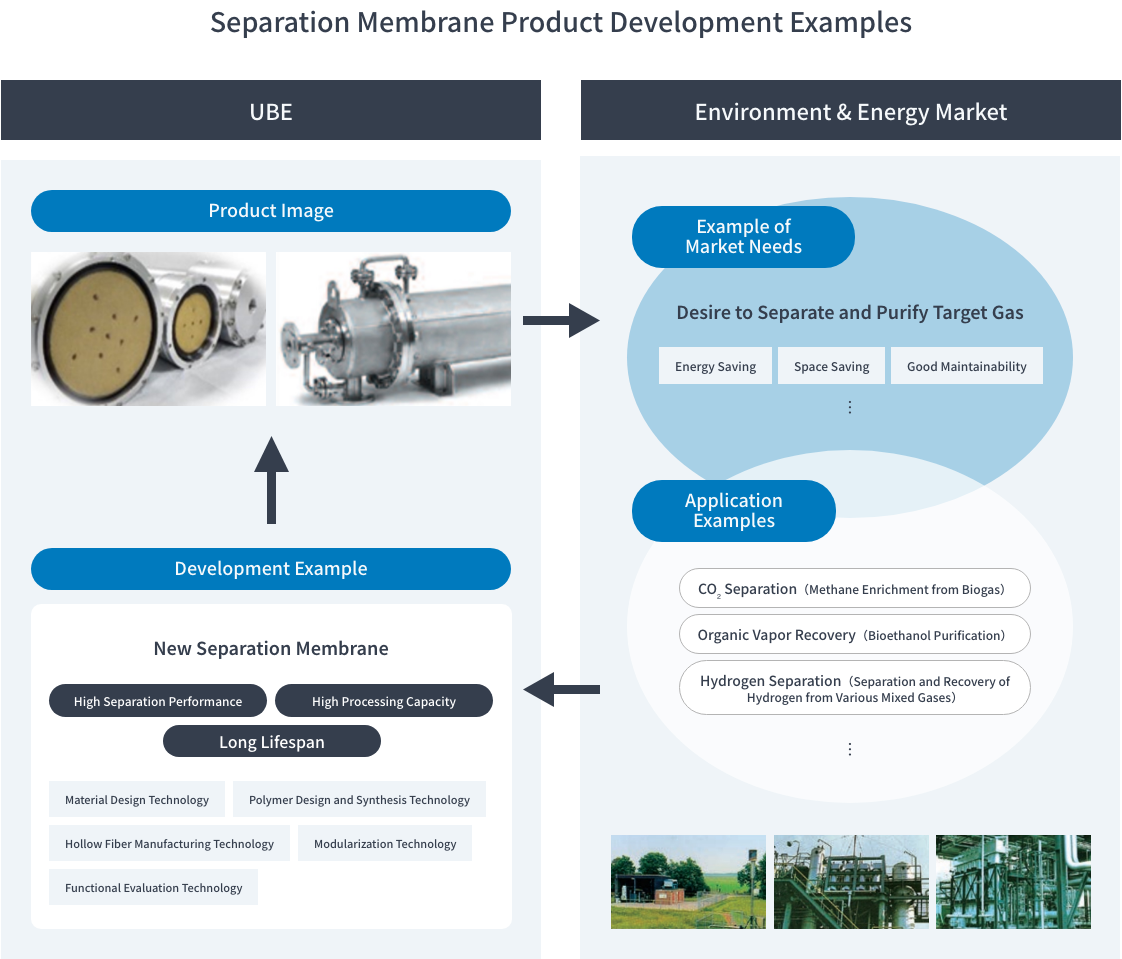

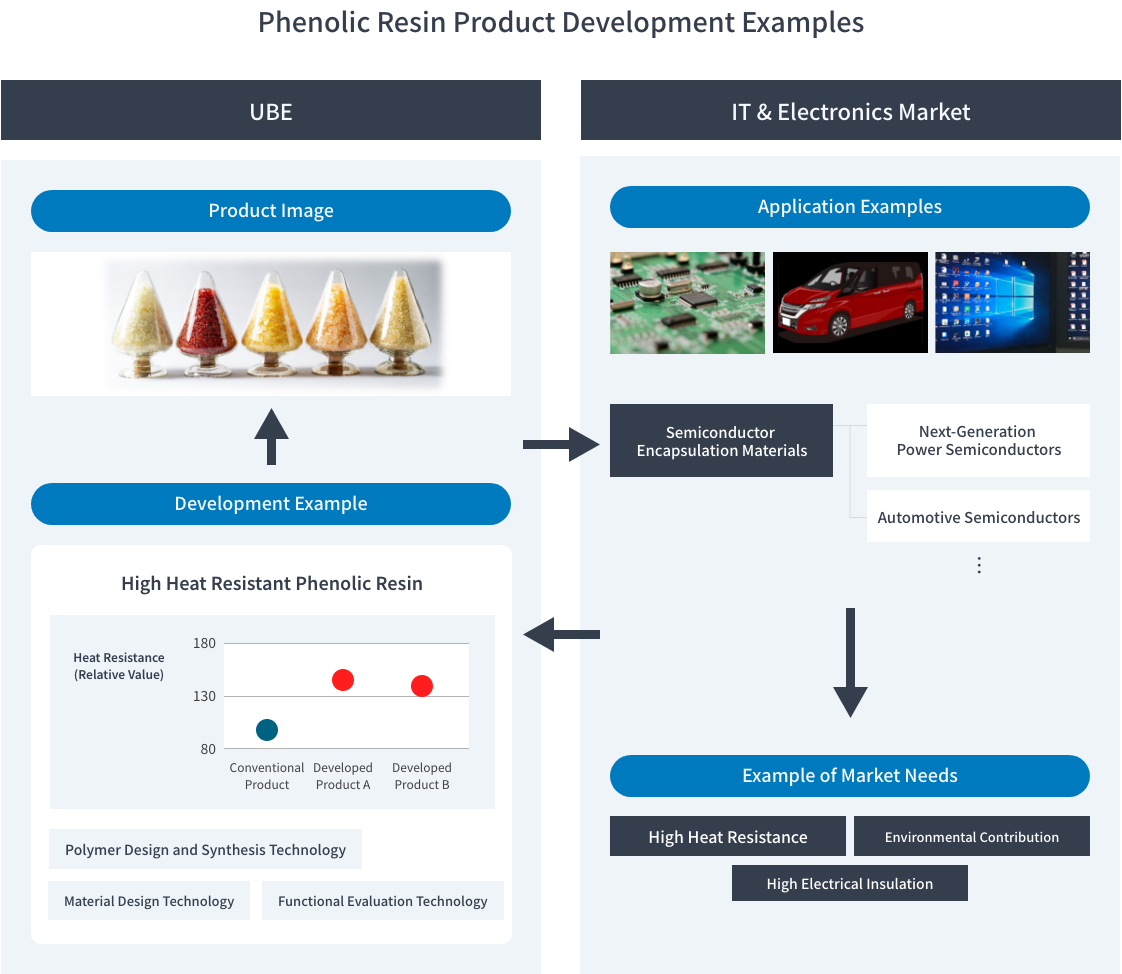

[Product Development] UBE is the world's only manufacturer with a fully integrated polyimide production chain from raw materials (BPDA*). Our department is involved in the development of polyimide products such as varnishes, films, and powders, as well as separation membranes utilizing polyimide hollow fibers. Additionally, UBE's phenolic resins play a crucial role in the supply chain of advanced industries such as semiconductors (e.g., epoxy resin hardeners for semiconductor encapsulation), and we are actively developing solutions to meet the needs of these applications.

*BPDA: Biphenyl Tetracarboxylic Dianhydride

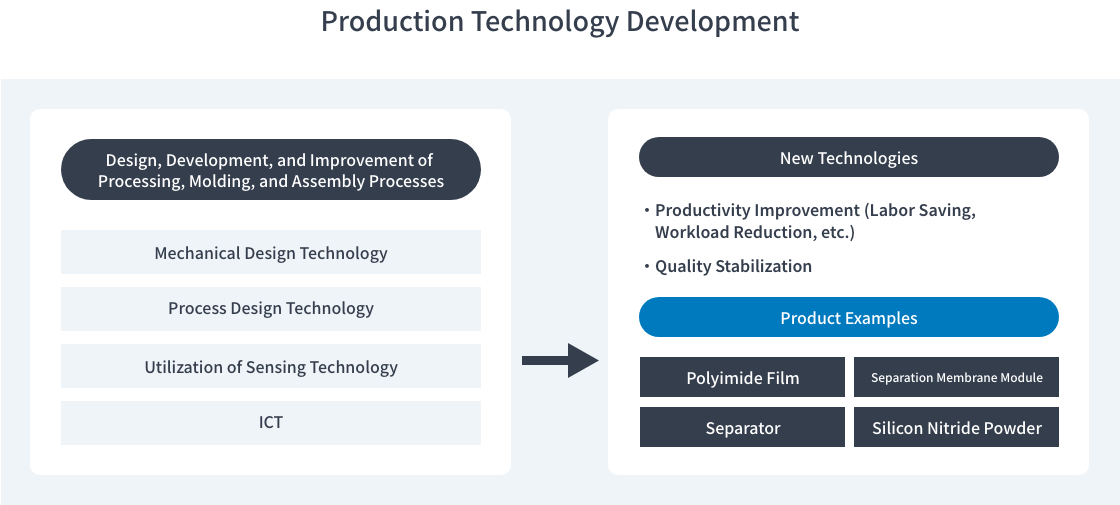

[Production Technology Development] Based on technologies such as mechanical equipment design and process engineering, we are also incorporating sensing technologies to develop new innovations that enhance productivity and stabilize quality.

Product / Technology Development Initiatives

Organization Overview

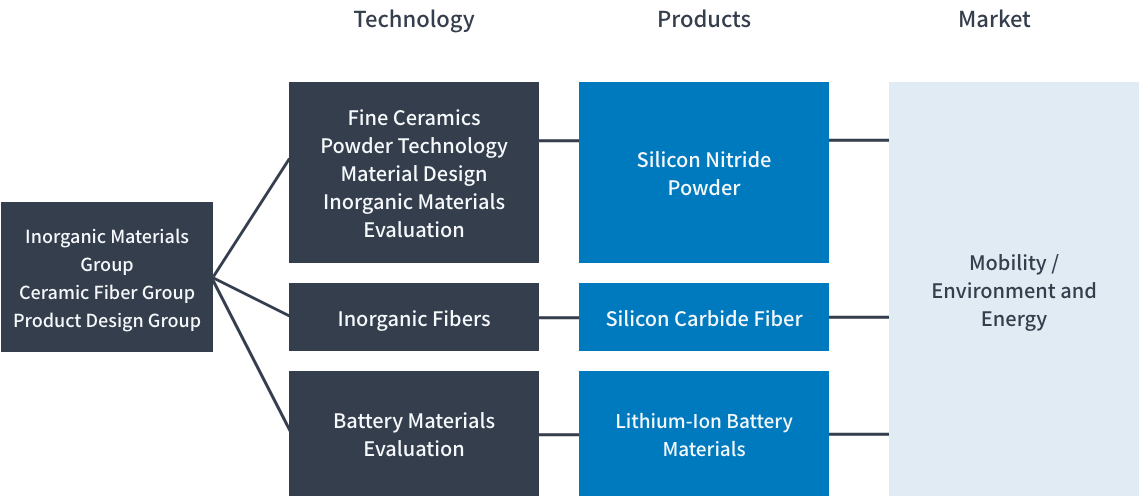

(Inorganic Materials Group, Ceramic Fiber Group,

Product Design Group)

Our department is responsible for research and development in the field of inorganic materials, enlarging UBE's specialty businesses. By combining UBE's proprietary inorganic synthesis technology, powder technology, spinning technology, and sintering technology, we are advancing the development of high-purity silicon nitride powder that outperforms our competitors, as well as Tyranno fiber®, an ultra-high heat-resistant fiber.

High-purity silicon nitride powder is used in a wide range of applications, from the automotive industry to aerospace, electronics, and machine tools, and has been highly regarded as the global standard for silicon nitride raw materials. In recent years, it has been utilized in xEV bearings and power module circuit boards to help realize a decarbonized society. Tyranno fiber®, an inorganic long fiber, is used in ceramic matrix composites as a reinforcement to increase toughness. It is expected to be a key material for improving the environmental performance of next-generation aircraft engines by enhancing fuel efficiency.

The platform technologies that have served these products are also being applied to the development of materials for next-generation lithium-ion batteries. Additionally, various evaluation technologies are crucial for maximizing material performances in these developments. By collaborating globally with other companies and research institutions, we refine evaluation techniques for various applications including ceramics and battery materials. Through research and development of inorganic materials, we address to create value that contributes a better future.

Technology / Market Overview

Main Development Products

-

Silicon Nitride Powder

-

Silicon Carbide Fiber

-

Lithium-Ion Battery Materials

Structure / Development Bases

UBE has development bases,

located across Japan.