2025/11/13

2025/11/13

Polyimide Binder for Li-ion Battery

Overview

Lithium-ion batteries have excellent energy storage capabilities and have been adapted to a variety of applications such as smartphones, drones, and automobiles.For example, a smartphone can withstand more than one day of use with a short charging time, and a car can reach a range of several hundred kilometers on a single charge.However, batteries adapted to any of these applications have the problem of very long recharging times. To overcome this challenge, battery manufacturers are focusing on developing batteries with higher energy density and higher input/output density.

Graphite is conventionally used as the negative-electrode active material of lithium-ion batteries, and its theoretical capacity is 372 mAh/g. Since current lithium-ion batteries are able to draw performance close to this theoretical value, it is necessary to use an active material with higher capacity to further increase the capacity. In recent years, Si-based materials have attracted attention as such materials, and various studies have been conducted. On the other hand, it is also known that Si active materials expand and contract significantly during charging and discharging, and the stress generated during this process significantly shortens the battery life.

To solve this problem, UBE is developing polyimide binders that can suppress the short life of batteries.

NEWS

2025/11/13

2025/11/13

2025/11/ 6

2025/11/ 6

2025/6/24

2025/6/24

Water Solvent Polyimide Binder for Si-system anode

Features

-

1.Compatible with high-capacity Si-based anode

Polyimide binder for high-capacity Si-based anode

-

2.Low heat treatment temperatures possible

Aqueous solvent binders allow lower heat treatment temperatures than NMP solvent binders

- #PI varnish

- #battery

- #lithium-ion battery

- #binder

- #high capacity

Basic Properties of Polyimide Binder

| Existing PI (NMP Solvent) |

Under Dev. (NMP Solvent) |

Under Dev. (Water Solvent) |

Competitor's PI | Acrylic Acid | |

|---|---|---|---|---|---|

| Active material | Si,SiO,SiC Graphite /Si,SiO,SiC |

Si,SiO,SiC Graphite /Si,SiO,SiC |

Si,SiO,SiC Graphite /Si,SiO,SiC |

Si,SiO,SiC Graphite /Si,SiO,SiC |

Si,SiO,SiC Graphite /Si,SiO,SiC |

| Anode capacity(mAh/g) | ~4,000 | ~4,000 | ~2,000 | ~1,500 | ~600 |

| Solvent | NMP | NMP | water | NMP | water |

| Solid content(%) | 18 | 30 | 18 | 18 | - |

| Heat treatment(˚Ϲ) | 250-350 | 200-350 | 150-350 | 300-400 | 80-160 |

| Storage temperature | <50˚C | <50˚C | <25˚C | <5˚C | <50˚C |

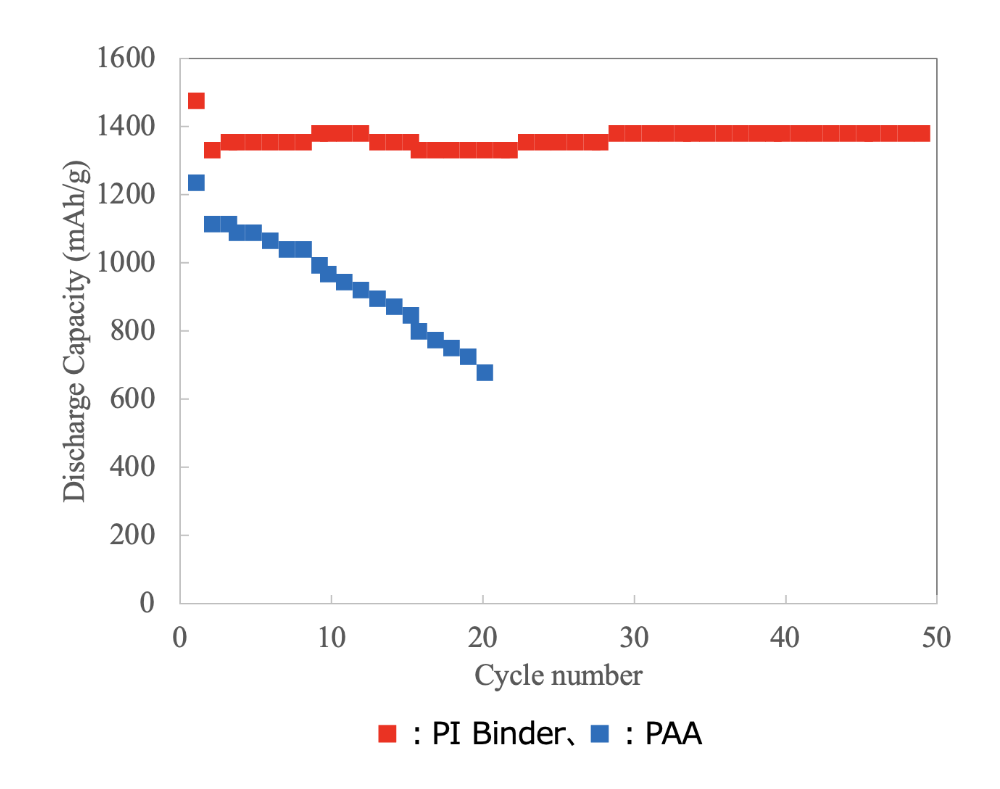

Comparison of Battery Performance

-

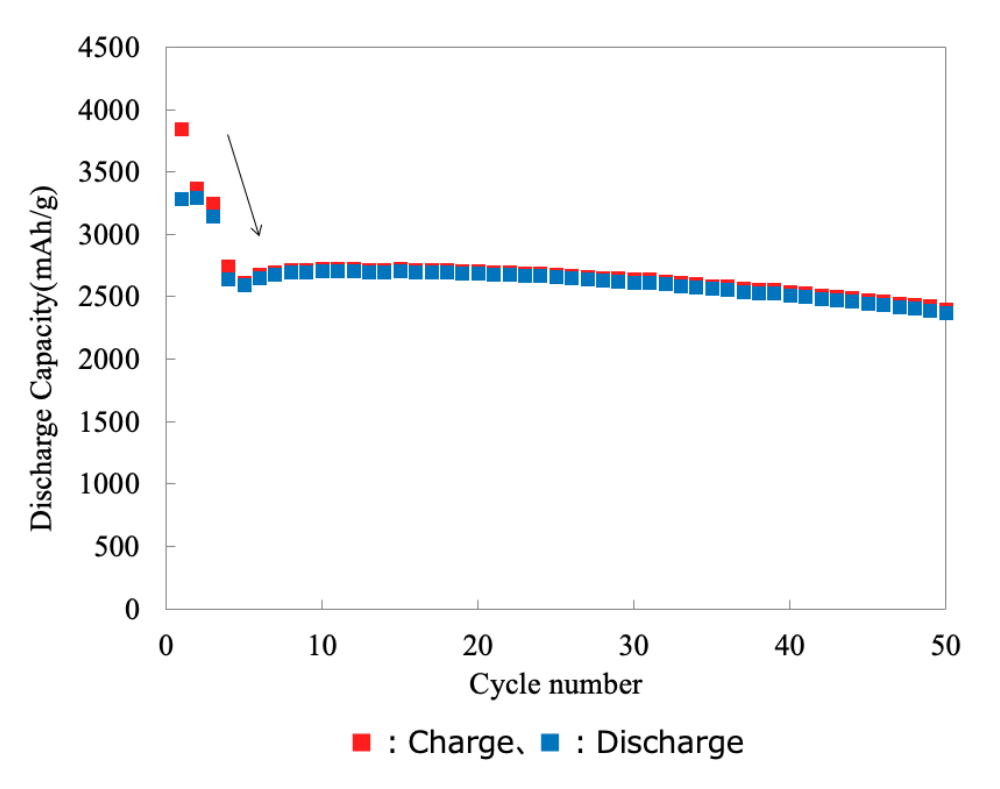

Cycle performance of Si anode (NMP Solvent)

Electrode configuration、Measurement condition

- ・Composition of anode Si : AB : PI

- ・Electrolyte 1M LiPF6 EC:DEC(1:1vol%) VC(1wt%)

- ・Weight: 3.0mAh/cm2

- ・Heat treatment: 350℃×1hr (Vacuum)

- ・Measurement condition: Temperature 30ºC, 0.1~0.5 CA、 0.001-1.0 V

-

Cycle performance of SiO anode(Water Solvent)

Electrode configuration、Measurement condition

- ・Composition of anode SiO : AB : CNT : PI or PAA

- ・Electrolyte 1M LiPF6 EC:DEC(1:1vol%) VC(1wt%)

- ・Weight: 2.0mAh/cm2

- ・Heat treatment: PI 150℃×12hrs (Vacuum)、PAA 120℃×12hrs (Vacuum)

- ・Measurement condition : Temperature 30ºC, 0.1CA、 0.001-2.0 V(1st)、 0.001-1.0V(2nd~)

-

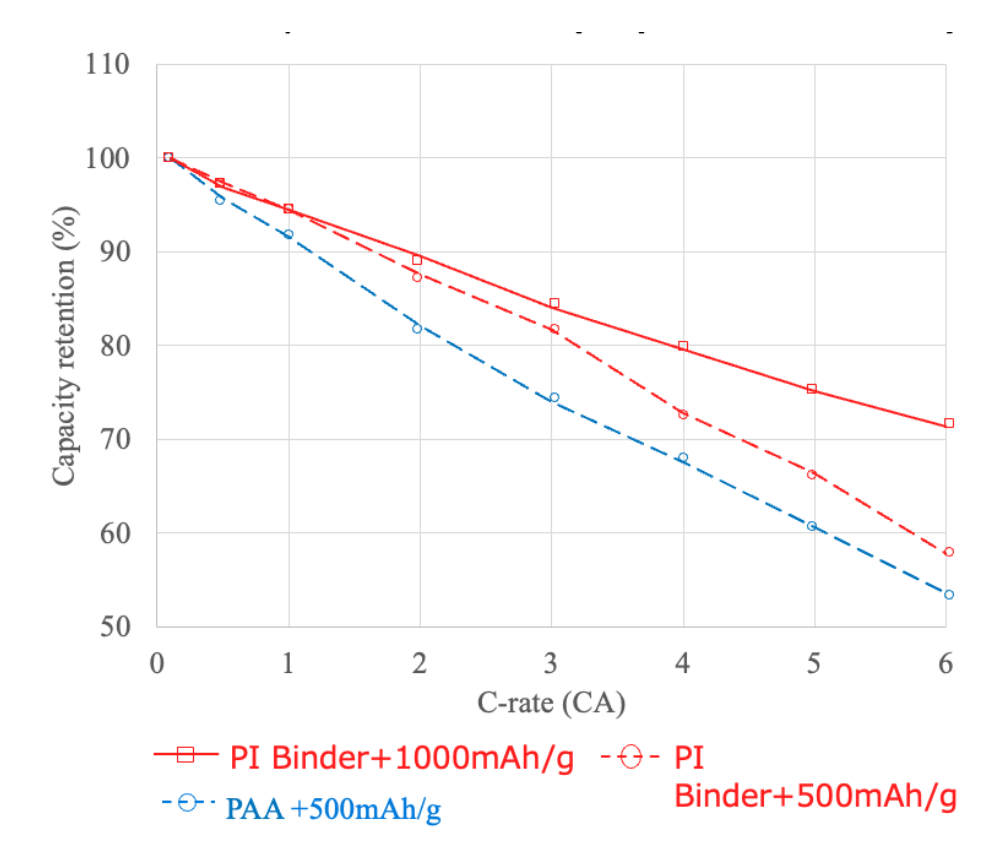

Comparison of rate performance (PI(Water Solvent) vs. PAA)

Electrode configuration

- ・Cathode: NCM811,

- ・Anode: Graphite + SiO

- ・Electrolyte 1M LiPF6 EC:ECM(3:7 vol%)

Battery evaluation

Yamagata University Innovation Center

for Organic Electronics

Dr. Masanori MORISHITA