UPIA - Covering, coating materials (Grade details)

Characteristics of "UPIA®"

(1) Composition of UBE Polyimide

"UPIA®" is a polyimide precursor formed from UBE's proprietary "BPDA(Biphenyl tetracarboxylic dianhydride)" monomers. This is the original UBE varnish.

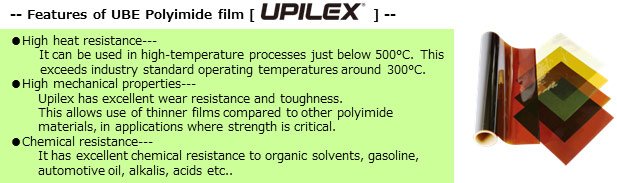

UBE polyimide film "UPILEX®" is produced using this unique UBE polyimide precursor giving it various and unique advantages. Polyimide coated film derived from the varnish of the same graded has the same properties.

Details of [UPILEX®] isHere.

(2) General properties of "UPIA®"

| Property | Category | Heat-resistant /High heat-resistant (Existing grade) | For secondary battery binder | Measurement condition |

|---|---|---|---|---|

| Unit | UPIA-AT/ST (U-Varnish-A/S) |

UPIA-LB | ||

| Solvent | - | *NMP | *NMP, Water | |

| Solid content | wt% | 17-19 | 10-30 | 350°C, 30min |

| Density | ×103kg/m3 | 1.10-1.11 | 1.05-1.15 | 25°C |

| Solution viscosity |

Pa·s | 5-100 | 0.1-10 | E-type, 30°C |

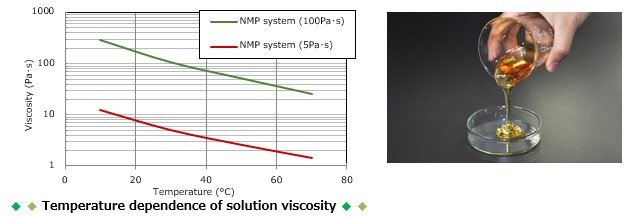

(3) Temperature dependence of solution viscosity

(4) Concentration dependence of solution viscosity

"UPIA®" can be used at any desired concentration by diluting it with anhydrous NMP or DMAc (N, N-dimethylacetamide).

(5) Storage stability

"UPIA®" has superior storage stability compared to conventional polyimide varnishes. It exhibits a very low increase in viscosity at room temperature, while conventional polyimide varnish must be refrigerated or frozen.

Other handling precautions are Here

Base grade

Heat-resistant varnish UPIA-AT (U-Varnish-A) / High heat-resistant varnish UPIA-ST (U-Varnish-S)

UPIA-AT, UPIA-ST is the same as the U-Varnish-A, U-Varnish-S.

UPIA-AT, UPIA-ST has received high praises of usability and high performance.

(1) Thermal properties

Polyimide film obtained from "UPIA®" exhibits a high thermal decomposition temperature. Especially, "UPIA®-ST(U-Varnish-S)" has a thermal decomposition temperature above 550°C, so it does not soften, fluidize, or decompose under use temperatures and it is able to be used in high-temperature processes.

In addition, the polyimide coating has excellent dimensional stability even at high temperatures.

| Property | Unit | UPIA-AT (U-Varnish-A) |

UPIA-ST (U-Varnish-S) |

Measurement condition/ Method |

|||

|---|---|---|---|---|---|---|---|

| 1001 | 1001 | ||||||

| Thickness | μm | 20 | 50 | 20 | 50 | ||

| Solvent | - | NMP | NMP | ||||

| Solid content | wt% | 18.0±1.0 | 18.0±1.0 | 350°C, 30min | |||

| Solution viscosity | Pa·s | 5±1 | 5±1 | E-type, 30°C | |||

| Heat treatment highest temp. |

°C | 350 | 450 | ||||

| Film properties | Glass-transition temp.Tg |

°C | 274 | 278 | 322 | 324 | Dynamic viscoelasticity |

| 5% weight reduction temp. |

°C | 592 | 599 | 619 | 620 | TGA | |

| Thermal linear expansion coefficient (50-200°C) | ppm/K | 33 | 29 | 3 | 8 | Fine linear dilatometer | |

(2) Mechanical properties

Polyimide coating derived from "UPIA®" demonstrates excellent mechanical properties, especially high tensile strength and abrasion resistance.

| Property | Unit | UPIA-AT (U-Varnish-A) | UPIA-ST (U-Varnish-S) | Measurement Method | |||

|---|---|---|---|---|---|---|---|

| 1001 | 1001 | ||||||

| Thickness | μm | 20 | 50 | 20 | 50 | ||

| Film properties | Tensile strength | MPa | 229 | 238 | 526 | 482 | ASTM D882 |

| Elongation | % | 92 | 99 | 35 | 40 | ASTM D882 | |

| Tensile modulus | GPa | 3.7 | 3.7 | 9.8 | 9.3 | ASTM D882 | |

(3) Electric properties

Polyimide coat obtained from "UPIA®" delivers a high electrical reliability, such as insulation.

| Property | Unit | UPIA-AT (U-Varnish-A) | UPIA-ST (U-Varnish-S) | Measurement condition/ Method | ||

|---|---|---|---|---|---|---|

| 1001 | 1001 | |||||

| Thickness | μm | 20 | 50 | 20 | 50 | |

| Breakdown voltage | kV | 7.7 | 10.3 | 7.0 | 10.2 | ASTM D149 |

| Volume resistivity | Ω·m | >1014 | >1014 | >1014 | >1014 | ASTM D257 |

| Surface resistance | Ω | >1016 | >1016 | >1016 | >1016 | ASTM D257 |

(4) Chemical-Resistant Properties

"UPIA®" has excellent resistance to common organic solvents and metallic salt solutions, and it also demonstrates better resistance to acids and alkalis than conventional products. In addition, it delivers superior performance when it comes to abrasion resistance and non- flammability.

| Chemical | Characteristic value (Thickness: 20μm) | |

|---|---|---|

| Strength retention rate (%) |

Elongation retention rate (%) |

|

| Methylene chloride | 95 | 96 |

| Chloroform | 88 | 90 |

| Trichloroethylene | 93 | 102 |

| Methyl ethyl ketone | 92 | 89 |

| Ethanol | 89 | 100 |

| Xylene | 99 | 84 |

| m-Cresol | 90 | 90 |

| N-methyl-2-pyroridon | 98 | 107 |

| Glacial acetic acid | 91 | 108 |

| 10% hydrochloric acid | 91 | 82 |

| 10% sulfuric acid | 93 | 94 |

| 2% sodium hydroxide | 99 | 91 |

| 10% sodium hydroxide | 82 | 81 |

Measurement condition: 30°C, 24h Dipping