2025/11/ 6

2025/11/ 6

UIP®-R, S

- UIP® Products and Features

- Application example

- Characteristics of UIP®

- Characteristics of UIP® Shapes

- Position and Features

- Process Flow of UIP® Shapes

- Application Example

NEWS

2025/11/ 6

2025/11/ 6

2025/10/ 1

2025/10/ 1

UIP® Products and Features

UIP® is an excellent heat-resistant polyimide powder, based on Biphenyl tetracarboxilic dianhydride (BPDA) originally developed by UBE.

UIP® products

UIP®-R Heat-resistance, high-impact ability, easy forming

UIP®-S Super heat-resistance, low creep, low water absorption, high modulus, high ablation resistance

UIP®-SA Super heat-resistance, low creep, low water absorption, easy forming

Common characteristic of UIP® : High chemical resistance, high radiation/plasma resistance, flame retardance

- #high heat resistance

- #high dimensional stability

- #low water absorption

- #shape

- #semiconductor

- #high-performance fillers

Application example

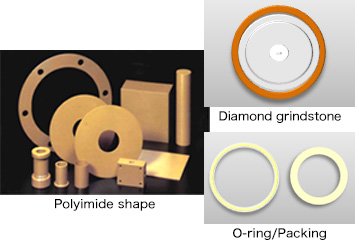

- Raw material of polyimide shape

- Binder for diamond grindstone

- Compound for PTFE, Fluorocarbon elastomer, Phenolic resins

Characteristics of UIP®

| Item | Unit | UIP®-R | UIP®-S | UIP®-SA |

|---|---|---|---|---|

| Average particle diameter |

µm | 7 | 8 | 13 |

| Specific gravity | - | 1.39 | 1.48 | 1.47 |

| Aerated bulk density |

g/cc | 0.29 | 0.38 | 0.34 |

| Angle of repose | deg | 44 | 52 | 46 |

| Temperature of 5% weight loss |

°C | > 580 | > 600 | > 600 |

| Moisture &volatile matter contents (50-350°C) |

% | < 1.0 | < 1.0 | < 1.0 |

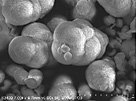

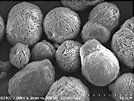

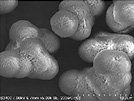

| SEM image | - |  |

|

|

Characteristics of UIP® Shapes

| Item | Unit | UIP®-R Shape |

UIP®-S Shape |

UIP®-SA Shape |

Measurement Method |

|---|---|---|---|---|---|

| Specific gravity | - | 1.39 | 1.47 | 1.48 | ASTM D-792 |

| Water absorption | % | 0.46 (48 hr) |

0.12 (48 hr) |

0.03 (24 hr) |

ASTM D-570 |

| Tensile strength | MPa | 120 | 80 | 110 | ASTM D-638 |

| Elongation | % | 5 | 2 | 4 | ASTM D-638 |

| Flexural strength | MPa | 160 | 100 | 140 | ASTM D-790 |

| Flexural modulus | GPa | 4.2 | 8.0 | 7.5 | ASTM D-790 |

| Izod Impact (notched) |

J/m | 75 | 22 | 20 | ASTM D-256 |

| Rockwell hardness | M scale | 114 | 113 | 115 | ASTM D-785 |

| Heat distortion temp. (1.82 MPa) |

°C | 360 | 500 | 470 | ASTM D-648 |

| Coefficient of thermal expansion |

ppm/°C | 55 (20-250°C) |

37 (20-250°C) |

35 (25-450°C) |

ASTM D-233 |

| Tabar abrasion loss | mg/1000 cycle | 15 | - | 20 | ASTM D-1044 |

| Limiting PV value | MPa·m/sec | 1.7 | 2.2 | - | S45C,0.5m/s |

Position and Features

Features Polyimide shape from UIP®

- Super high heat resistance

- Low outgas

- Good processability

- Low particles

Heat Distortion Temperature vs Flexural Modulus

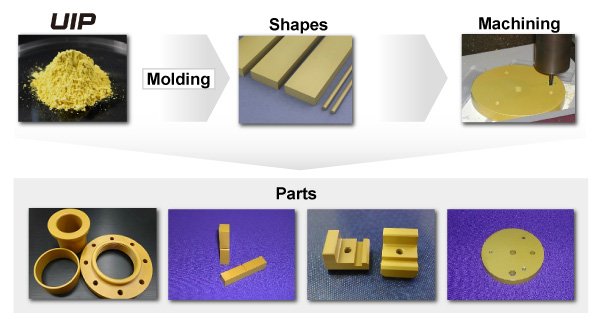

Process Flow of UIP® Shapes

UIP® can make you to lead into wide spreaded various application field

Application Example

Electronics

・Micro-switch

・Guide piece

・Bearing

・Center pin

・Vacuum pad

Automotive

・Friction pad

・Valve seat

・Bushing

・Trust washer

・Bearing retainer

Machine

・Bearing sleeve

・Roller bushing

・Vane

・Piston ring

Aerospace

・Seal ring

・Piston ring

・Gear

・Locknut insert