What are polyimides?

Polyimides

Explore the properties, benefits, and uses of polyimides, resins that are widely employed in electronic devices and other products because of their diverse advantages, including superb resistance to heat and chemicals.

Overview

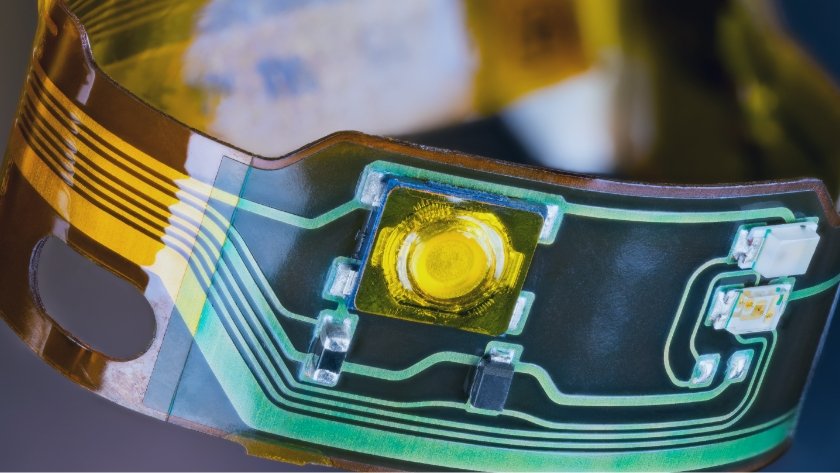

Polyimides are everywhere, including in your smartphone

Like polyamides (nylon), polyimides are a family of engineering plastics that are superior to standard plastics in characteristics such as mechanical strength and resistance to heat and chemicals. With a melting point of over 450°C, polyimides offer even greater heat resistance than polyamides (around 200°C), and exhibit almost no expansion or other dimensional changes under temperatures ranging from -196°C to 300°C. This unparalleled advantage enables polyimides as films or powders to be used in all sorts of products, including automobiles and consumer electronics. In fact, polyimides are indispensable to the circuit boards found in everyday electronics such as smartphones, computers, and LCD televisions.

Features

From aerospace to microelectronics

Polyimides stand up to high temperatures even as thin films, but that's not all. They excel in many other characteristics, including mechanical properties, flame retardancy, electrical insulation, low dielectric constant, and resistance to chemicals and radiation. Also, they show almost no physical changes across a broad temperature range, from cryogenic to super hot. Because of their low thermal expansion coefficient, they are dimensionally stable, meaning that they maintain their shape and size. Since they are highly chemical resistant, they are not dissolved by organic solvents. Polyimides are readily processable into diverse forms, such as films, coatings (varnish), and powders. This enables use in many different applications in semiconductor devices such as microelectronics, displays, and communication equipment.

A supporting actor that enhances product performance and reliability

Our polyimide products are used in diverse fields, and include offerings such as UPILEX® films that boast top-class heat resistance and electrical insulation; UPIA®, a polyamic acid precursor solution of polyimide that provides superb mechanical properties and chemical resistance; and UIP® powder that withstands super-high temperatures and can be used as a raw material for molded polyimide. Our superbly heat resistant polyimide films are manufactured in-house using our exclusive BPDA (biphenyl tetracarboxilic dianhydride) monomers, and are especially outstanding in terms of low water absorption, dimensional stability, and chemical resistance. We also have a film surface functionalization technology that maintains the core properties while responding to various functional requirements by adding the necessary functions or characteristics to the film surface.

We offer a broad lineup of super heat-resistant polyimide films made with BPDA. The standard grade, UPILEX®-S, is a polyimide film with superior mechanical properties that is used in a broad spectrum of applications requiring high reliability, including circuit board tapes bonded with semiconductors--an essential component of electronic devices--and OA equipment.

UPILEX®-RN, a molding grade polyimide film, offers high processability and is utilized for insulation, embossing, and speaker diaphragms, among other applications.

UPIA®, a polyimide coating solution, can be applied to metal and other substrates and baked at a high temperature to produce a polyimide film that excels in heat/chemical resistance and electrical insulation. It is mainly used in laser printer belts, substrates for laptop computers and LCD monitors, insulating coating for enameled wires, adhesive for the material parts of lithium-ion batteries, and so on.

UIP® is a powdered resin filler (material added to a base resin to enhance physical properties) that boasts top-class heat resistance. Its high thermal deformation temperature and superb chemical resistance prevent dissolution in various solvents. It is used as a chemical that improves or modifies the characteristics or performance of resins, and as an additive that strengthens grindstones made of diamond, etc.

<Polyimide products and their features>

UPILEX®

・High heat resistance (high glass transition temperature and thermal decomposition temperature)

・High tensile strength and elasticity

・Excellent electrical insulation and low dielectric constant

・Superb solvent resistance

- UPILEX®-S

Maintains high performance even at high temperatures

- UPILEX®-RN

Low elasticity and high elongation in high temperature ranges

UPIA®

・Outstanding mechanical properties (high tensile strength and elasticity)

・Excellent electrical insulation

・High heat resistance (high decomposition temperature and glass transition temperature)

・Superior chemical resistance (acids, alkalis, etching liquids)

UIP®

- UIP®-R

High resistance to heat and impact, highly moldable

- UIP®-S

Super heat resistance, low creep, low water absorption, high elasticity, strong abrasion resistance

- UIP®-SA

Super heat resistance, low creep, low water absorption, high processability, easily micromachinable

Features common to all grades:

Resistance to chemicals, radiation, and plasma; flame retardancy

Applications

Films that withstand heat and cold, resist abrasion, and provide electrical insulation

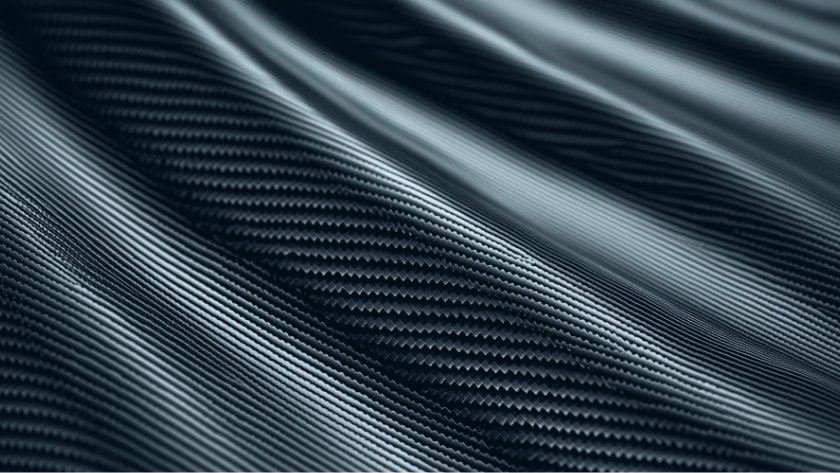

Offering superb resistance to high temperatures and mechanical stresses, polyimide films are used in devices requiring outstanding reliability. Because of their high intermolecular strength, they are often used for insulative protection of critical devices in the aerospace and defense industries, providing heat resistance and insulation of semiconductors. They are also used in CFRP (carbon fiber-reinforced plastic) release paper (film for protecting the surface of adhesive materials). Moreover, their easy processability means that they can be turned into varnishes and powders, making them an unsung hero of many applications in everyday life.

Polyimide films also demonstrate their diverse advantages in mobile phones, LCD televisions, and other products with display screens that are essential to our daily routines. In addition, they are gaining attention as a material for organic EL displays, which are thinner screens that emit light but not heat.

Polyimides at work in cutting-edge technology

UBE's technological pursuits include development of polyimide binders, which are used as a material in lithium-ion batteries. These batteries discharge and recharge through the movement of lithium ions between the cathode and anode. Their rechargeability makes them a versatile power source for a wide range of products, including mobile phones, computers, drones, and electric cars and motorcycles.

Our polyimide binder serves as a "glue" for lithium-ion batteries, keeping together the powdered material contained in the cathode and anode and fixing it to the surface of the metal foils.

Meanwhile, our UPIA®-LiB lineup of polyimide binders includes a water-soluble version that can be heat processed at temperatures lower than that of standard binders. We also work with universities and other research centers to demonstrate the functionality of high-performance polyimide binders.

As for polyimide powders, we have developed PETI®-330 as a polyimide additive. This resin melts at 200°C but then solidifies again at 370°C, a property that makes it useful as a binder that enhances performance in items such as aircraft parts, industrial machinery parts, diamond tools, and friction materials.

As a company committed to resolving environmental challenges, we have developed UPIA®-NF as an environmentally friendly polyimide varnish that uses water as a solvent instead of N-methyl-2-pyroridon or other high-melting-point organic solvents used in conventional polyimide varnishes. In this way, we help industries to lower their energy costs and avoid the issue of organic solvent disposal.

Our endless pursuit of research enables us to keep creating new polyimide solutions that address changes in the industrial landscape--and thus expand the possibilities for the future.