Polyimide NEWS

AABC appendix data : Applicability of Water Solvent Polyimide Binder for Si-system anode

2025/1/28

2025/1/28

UBE announced that we attend the 24th Annual Advanced Automotive Battery Conference (AABC) on 10 – 12 December 2024. We reported on “Polyimide Binder for Lithium-ion Battery”, which is applying water solvent, at the poster session. The additional data of Water solvent polyimide binder is shown as below contents. The data has been obtained that polyimide binder are effective for Si-system materials.

Serial Coating Trial and Charge-Discharge Evaluation of SiO Electrodes Using Newly Developed Polyimide Binder

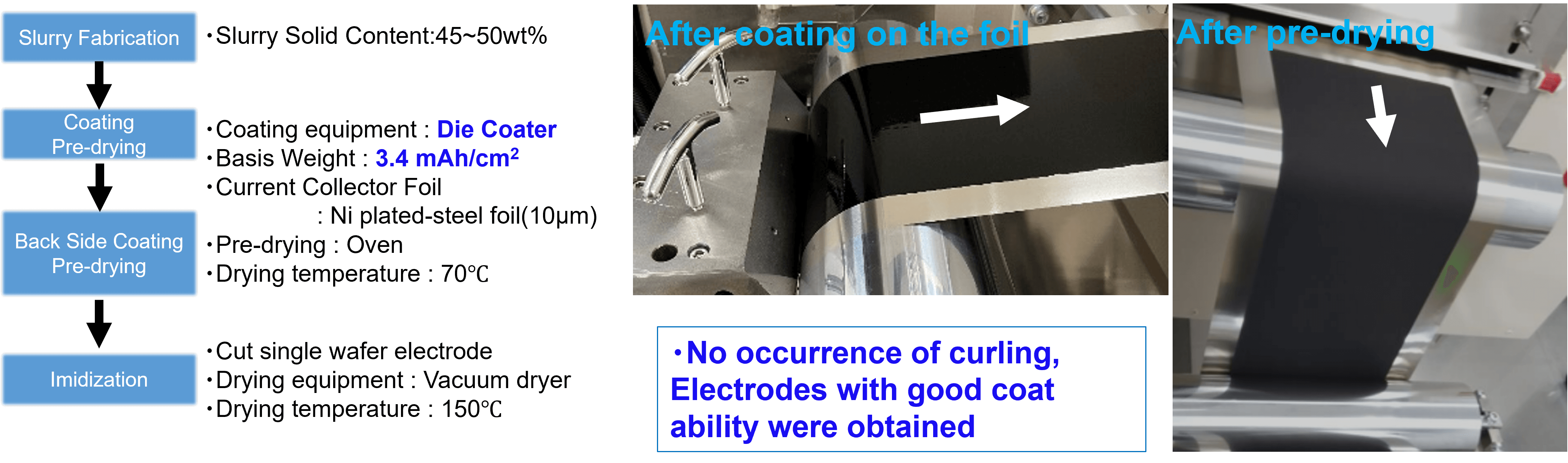

In roll-to-roll coating electrode, no occurrence of curling and electrodes with good coat ability were obtained.

Composition of Negative Electrode

| SiO (1400mAh/g) wt% |

Binder wt% |

AB wt% |

MWCNT wt% |

SWCNT wt% |

Basis Weight mAh/㎠ |

|---|---|---|---|---|---|

| 78.0 | 7.0 | 14.7 | 0.2 | 0.1 | 3.4 |

How to make Negative Electrode

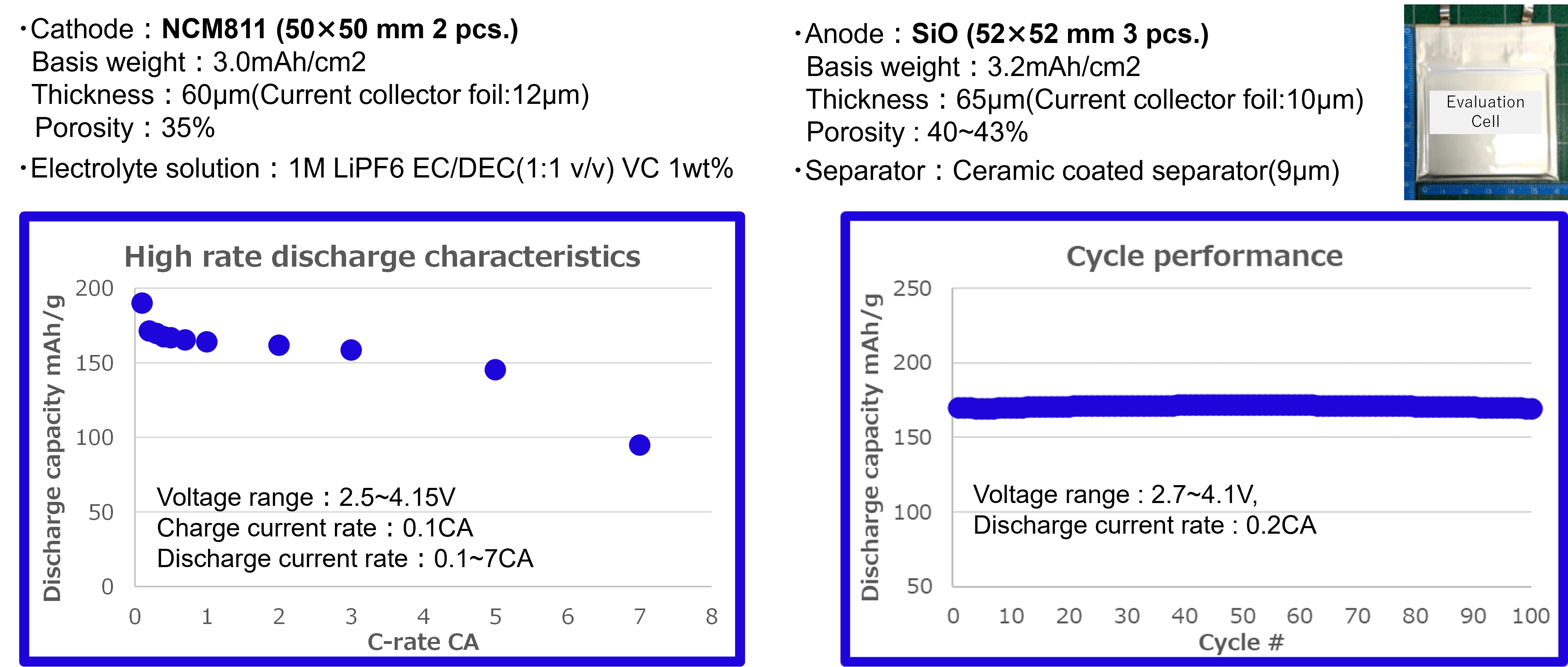

Evaluation of 300mAh class cells using prototype electrodes

Heat treat roll-to-roll coating electrode at 150℃.Laminated cell is shown excellent high-rate discharge characteristics and cycle performance.

・Design of 300mAh laminated cell

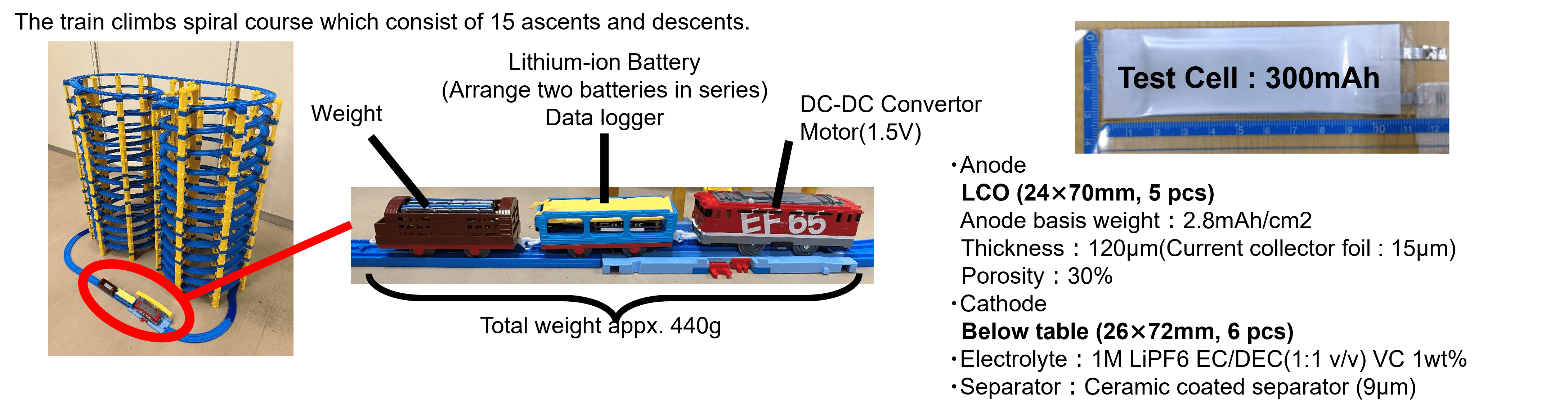

Application demonstration using prototype electrodes

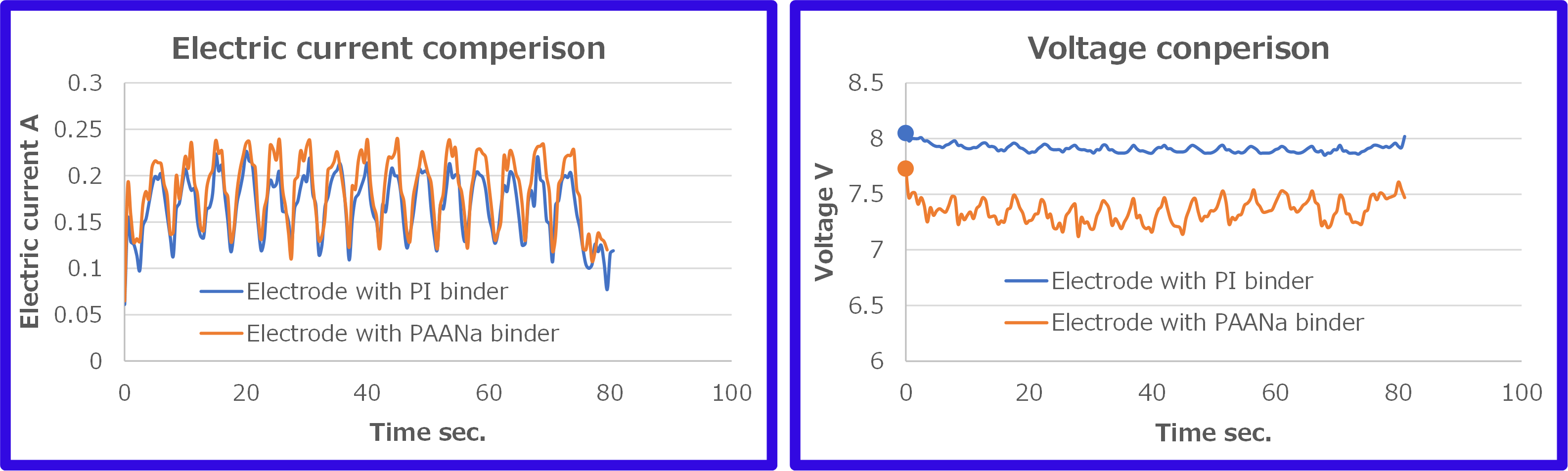

Implemented verification of roll-to-roll electrode performance applying electric toy. Visualize both voltage and current on working the application and find out advantage of newly polyimide binder.

Application:Plarail® ,which is electric train toy.

Cathode (Compared at SOC 100 after aging.)

| Binder | SiO wt% |

Binder wt% |

AB wt% |

MWCNT wt% |

SWCNT wt% |

Basis Weight mAh/㎠ |

Thickness µm |

|---|---|---|---|---|---|---|---|

| ① Water based PI |

78.0 | 7.0 | 14.7 | 0.2 | 0.1 | 3.2 | 68 |

| ② PAANa |

78.0 | 7.0 | 14.5 | 0.4 | 0.1 | 3.2 | 70 |

Left:Polyimide Binder Right:PAANa Binder