Polyimide NEWS

Applicability of NMP Solvent Polyimide Binder for

Si-system anode

2024/12/11

2024/12/11

UBE announced that we attend the 24th Annual Advanced Automotive Battery Conference (AABC) on 10 – 12 December 2024.

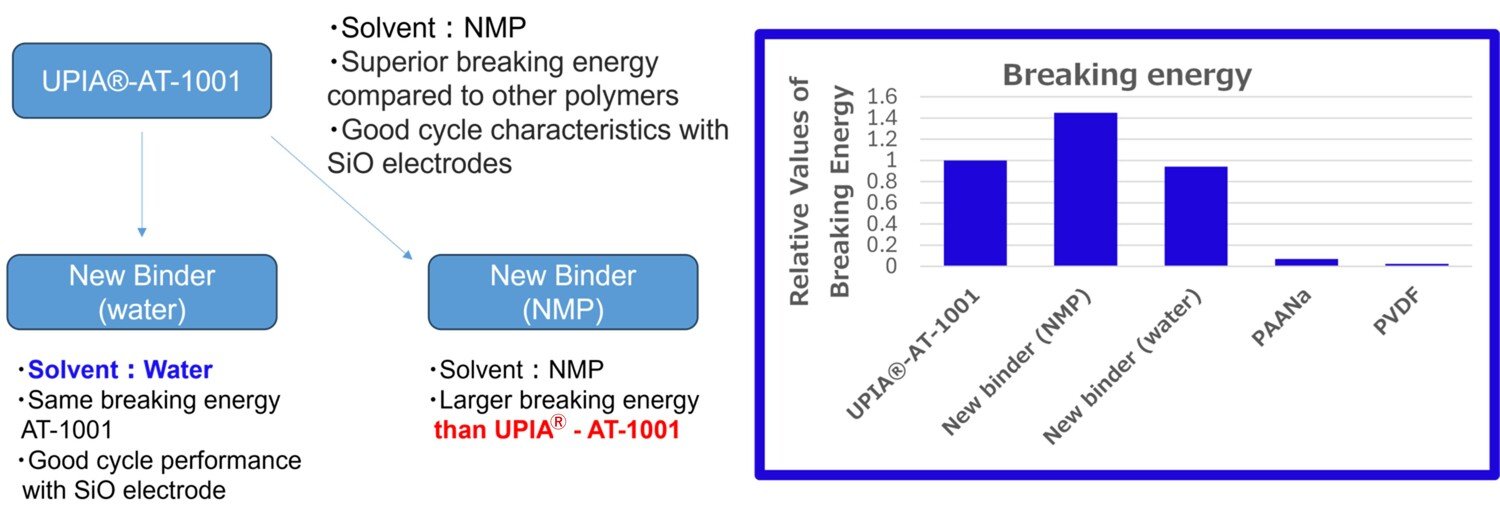

We reported on “Polyimide Binder for Lithium-ion Battery”, which is applying water solvent, at the poster session. Data of NMP solvent polyimide binder is shown as below contents. The data has been obtained that polyimide binder are effective for Si-system materials.

Applicability of Polyimide binder for Si-system anode

Trend towards high capacity and high input/output.

The use of Si-based active materials with large theoretical capacity is actively being studied.

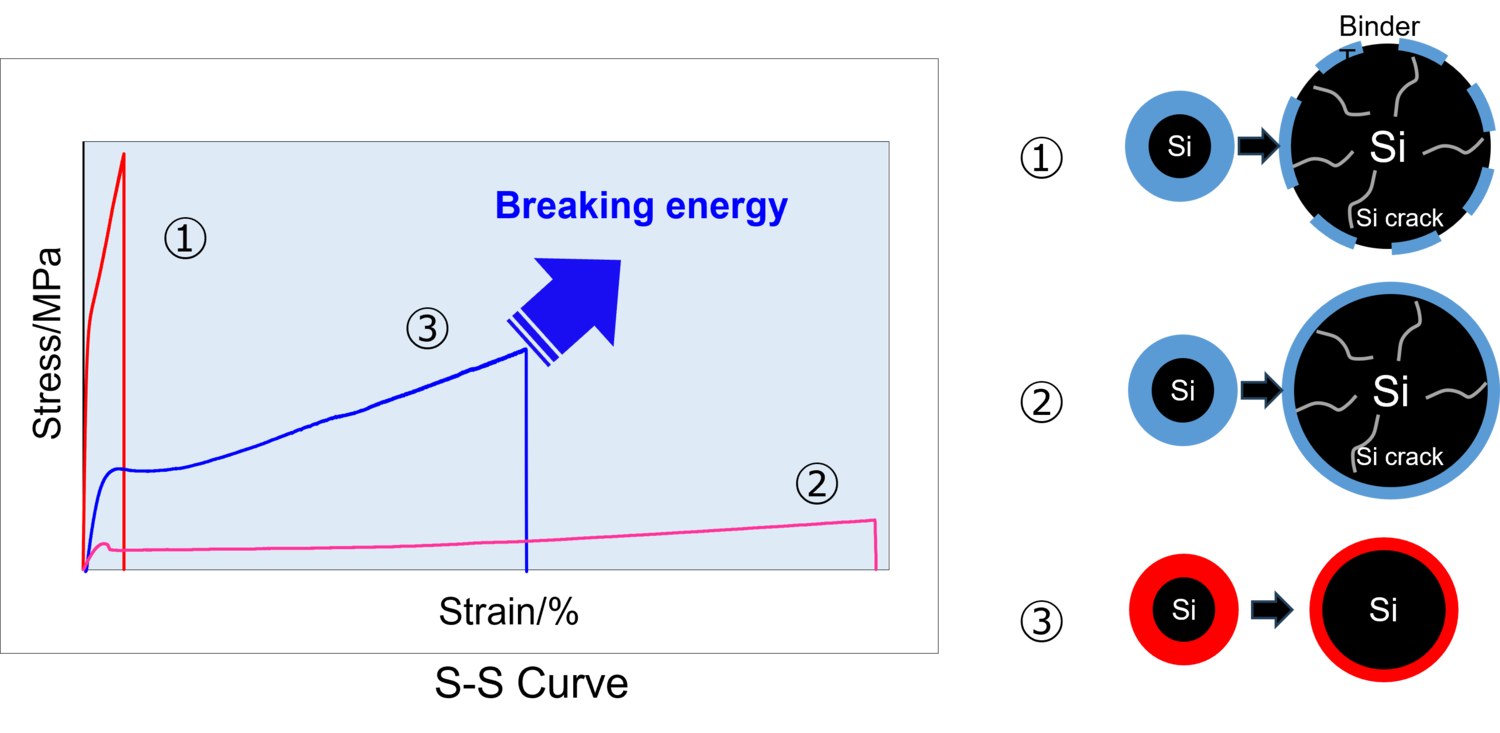

Issues: pulverization and cycle degradation due to large expansion and contraction.

Requirements for binders:

It is assumed that it is important to have a high “breaking energy,“

which is an indicator of the durability until the binder breaks

Breaking energy MJ/㎥ = S-S Curve Square

・High breaking energy = Potential applicable of Polyimide binder

High strength Polyimide binder for Lithium-ion battery

(NMP solvent)

High strength Polyimide binder for Lithium-ion battery (NMP solvent)

・Developed an NMP-based polyimide binder with enhanced strength by improving UPIA®-AT-1001

・Potential applicability to pure Si, which has an even higher capacity than SiO

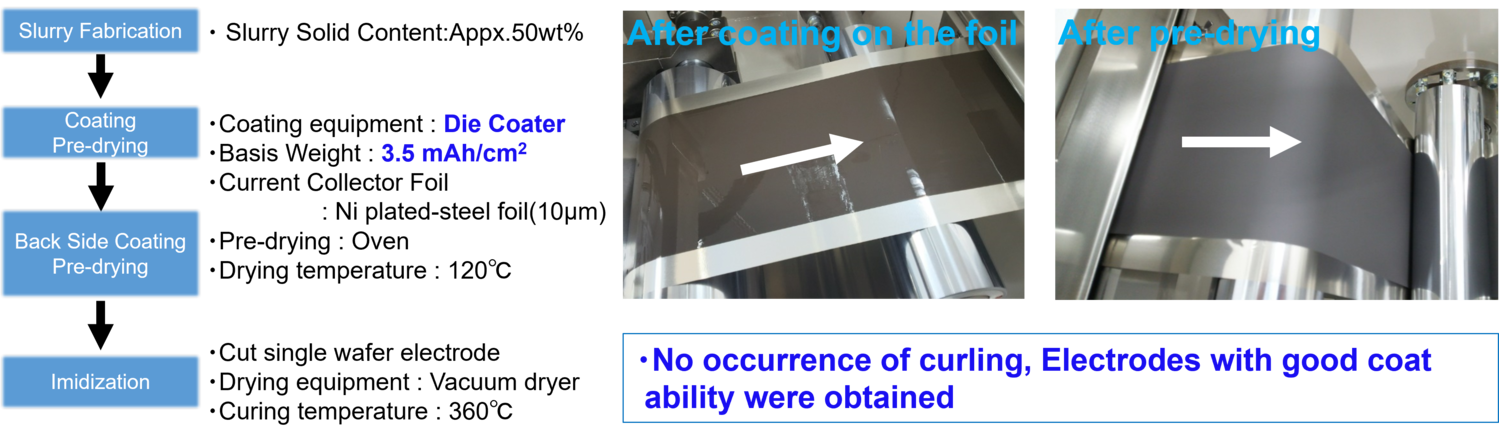

Serial Coating Trial and Charge-Discharge Evaluation of

Si Electrodes Using Newly Developed Polyimide Binder

(NMP Solvent)

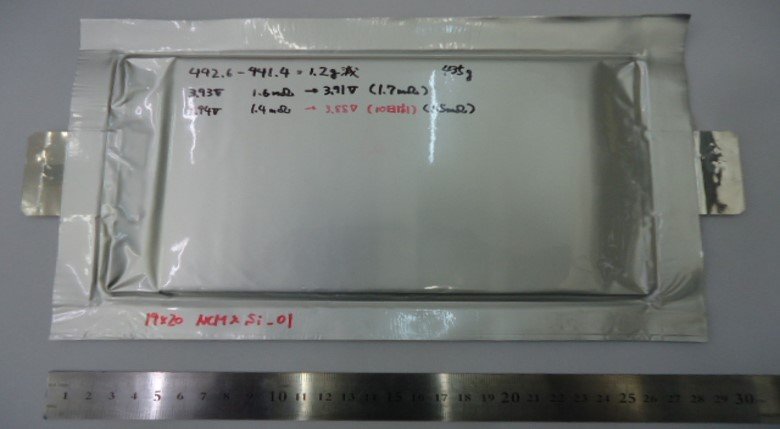

In roll-to-roll coating electrode, no occurrence of curling and electrodes with good coat ability were obtained.

Composition of Negative Electrode

| Si(3000mAh/g) wt% |

Binder wt% |

AB wt% |

|---|---|---|

| 72.0 | 18.0 | 10.0 |

How to make Negative Electrode

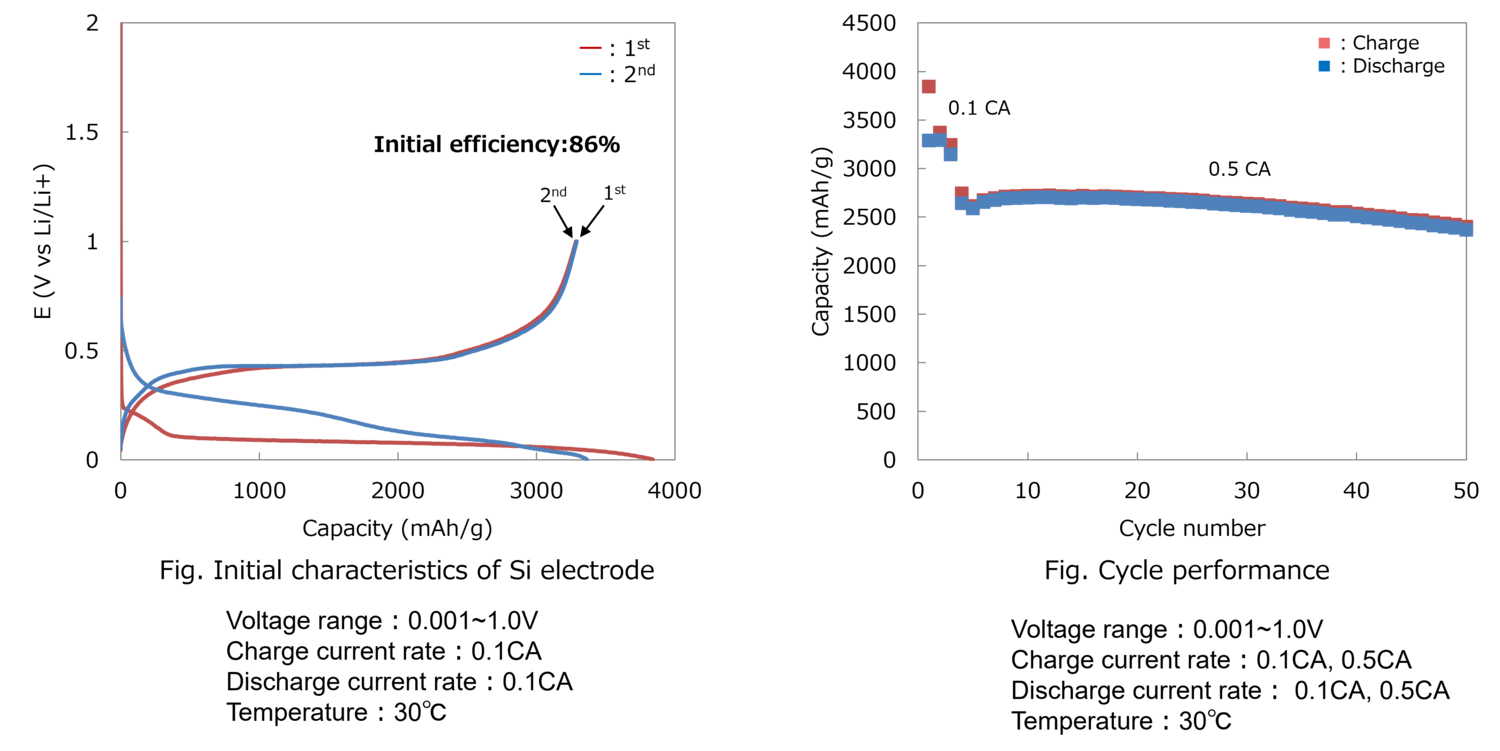

Charge-discharge evaluation of Si Electrodes Using Newly Developed Polyimide Binder(NMP Solvent)

Fabrication of full-cell using prototype Si electrode

・Fabricated a full cell to verify the performance of the prototype electrode.

・Fabricated a full cell using graphite as a comparison electrode.

・Monitored the internal state of the battery and compared performance when applying the current load that flows when the drone moves up, down, left, right, or hovering.

| Silicon Electrode | Cf. Graphite Electrode | ||

| Anode | Silicon (3.5 mAh/㎠) |

Artificial Graphite (3.5 mAh/㎠) |

|

| Cathode | Ternary system (3.0 mAh/㎠) |

Ternary system (3.0 mAh/㎠) |

|

| Separator | Ceramic coated separator(19µm) | ||

| Electrolyte | 1M LiPF6 EC:DEC (1:1)+1wt%VC | ||

| Cell Dimension |

Thickness | 5.5±3 mm | |

| Length | 188±2 mm | ||

| Width (Inc. Tab) |

317±2 mm | ||

| Weigh | 442 g | 370 g | |

| Rated Capacity | 22 Ah (@25℃) | 16 Ah (@25℃) | |

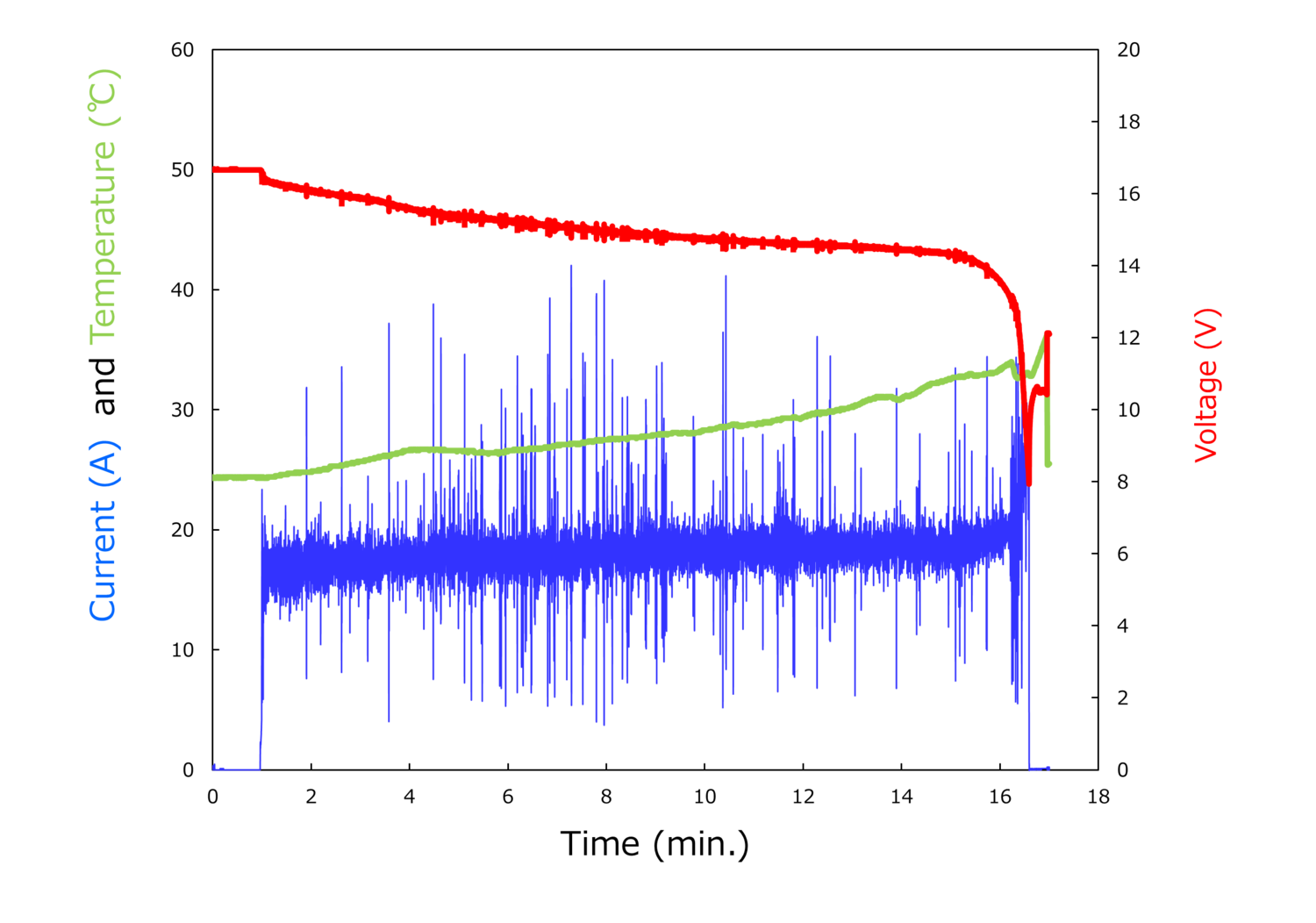

Doron simulation using prototype Si electrode

Output confirmation during drone flight

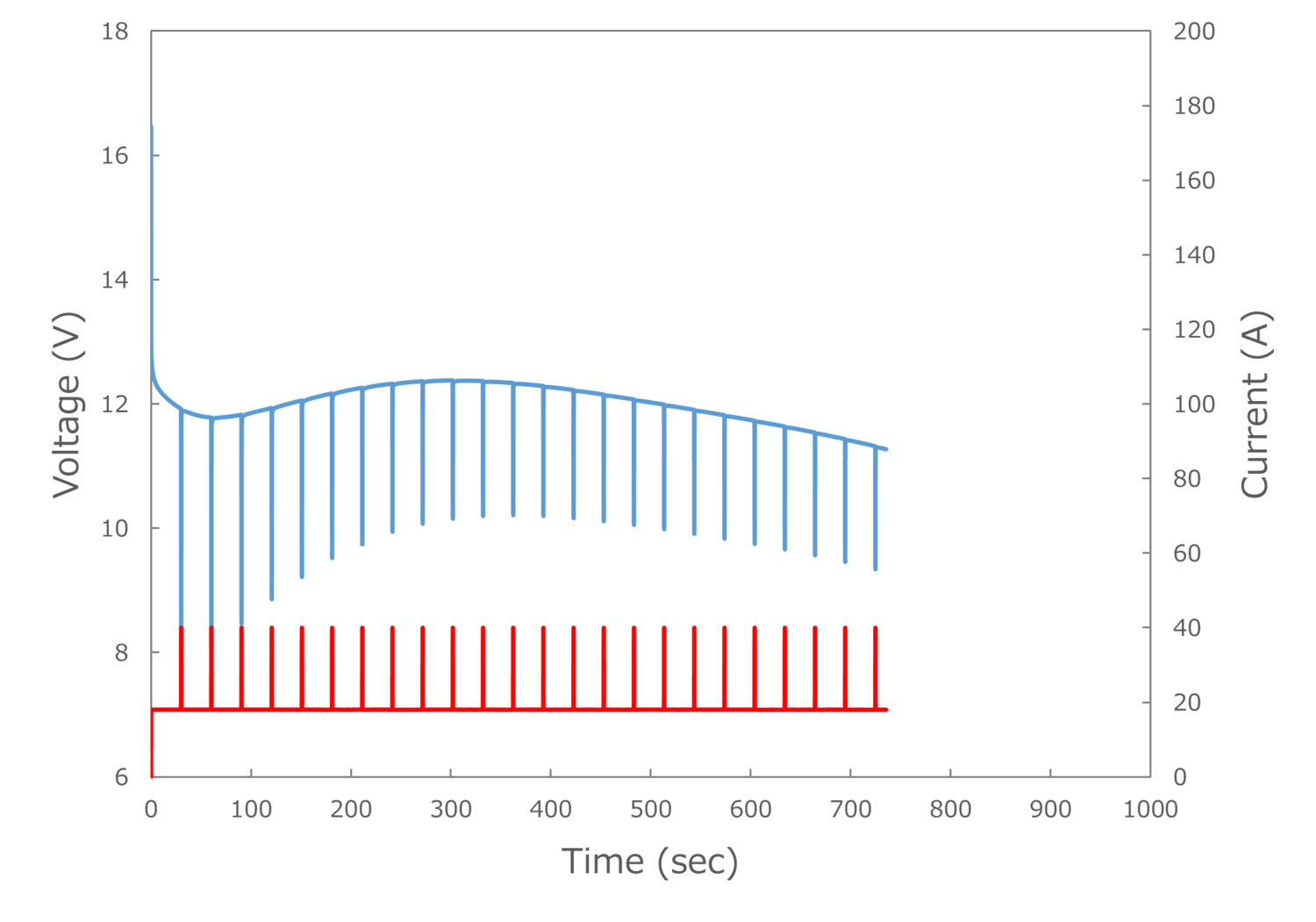

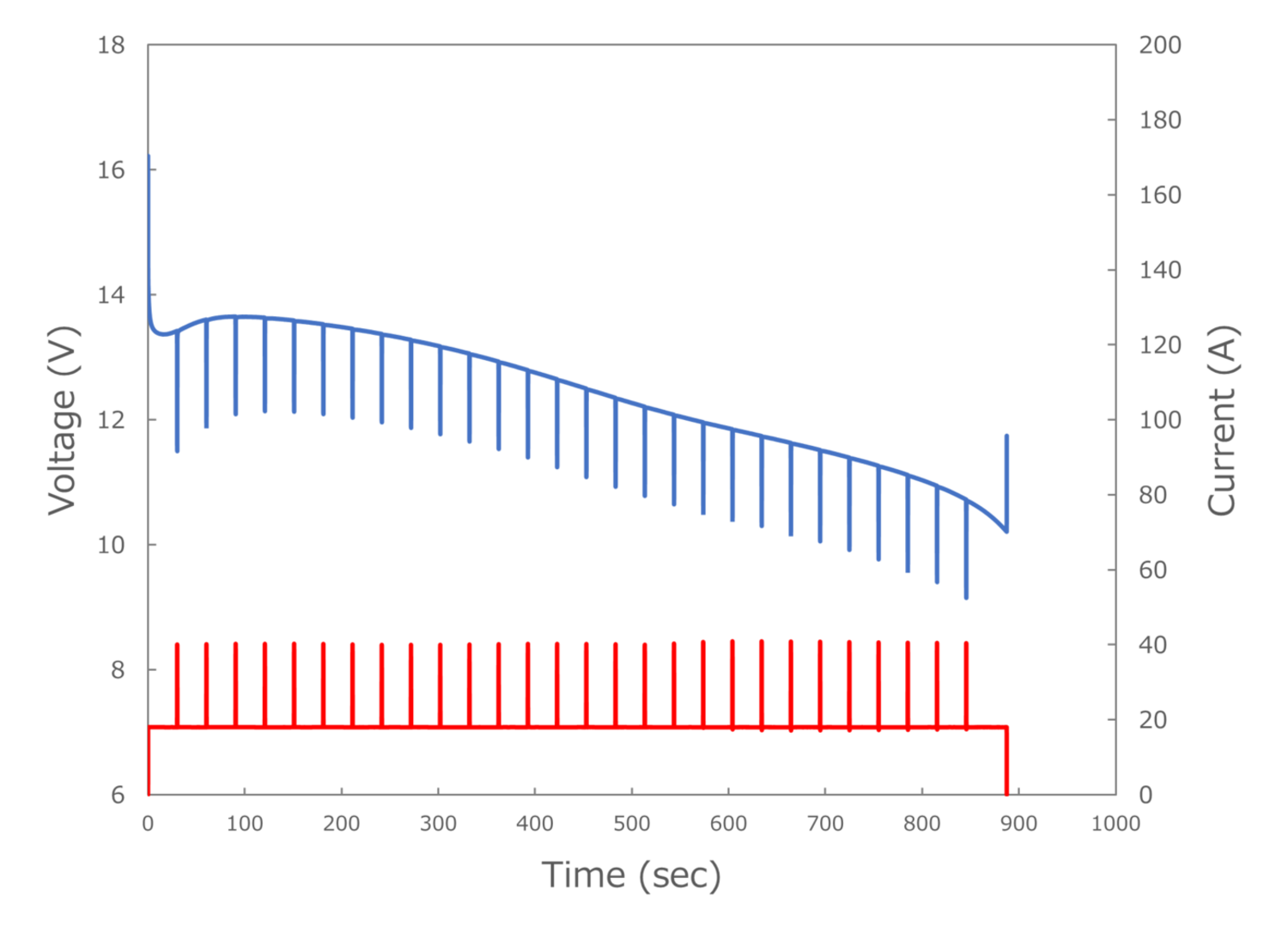

【Voltage during flight and current profile】

| Current value during flight / C-rate |

Max current value /C-rate |

Battery Temperature | Flight time |

|---|---|---|---|

| 15-23 A 2.9-4.5CA |

41.5 A 8.1CA |

33℃ | 15.6min |

Measure the current value during flight and calculate the current value required for movement in all directions and hovering.

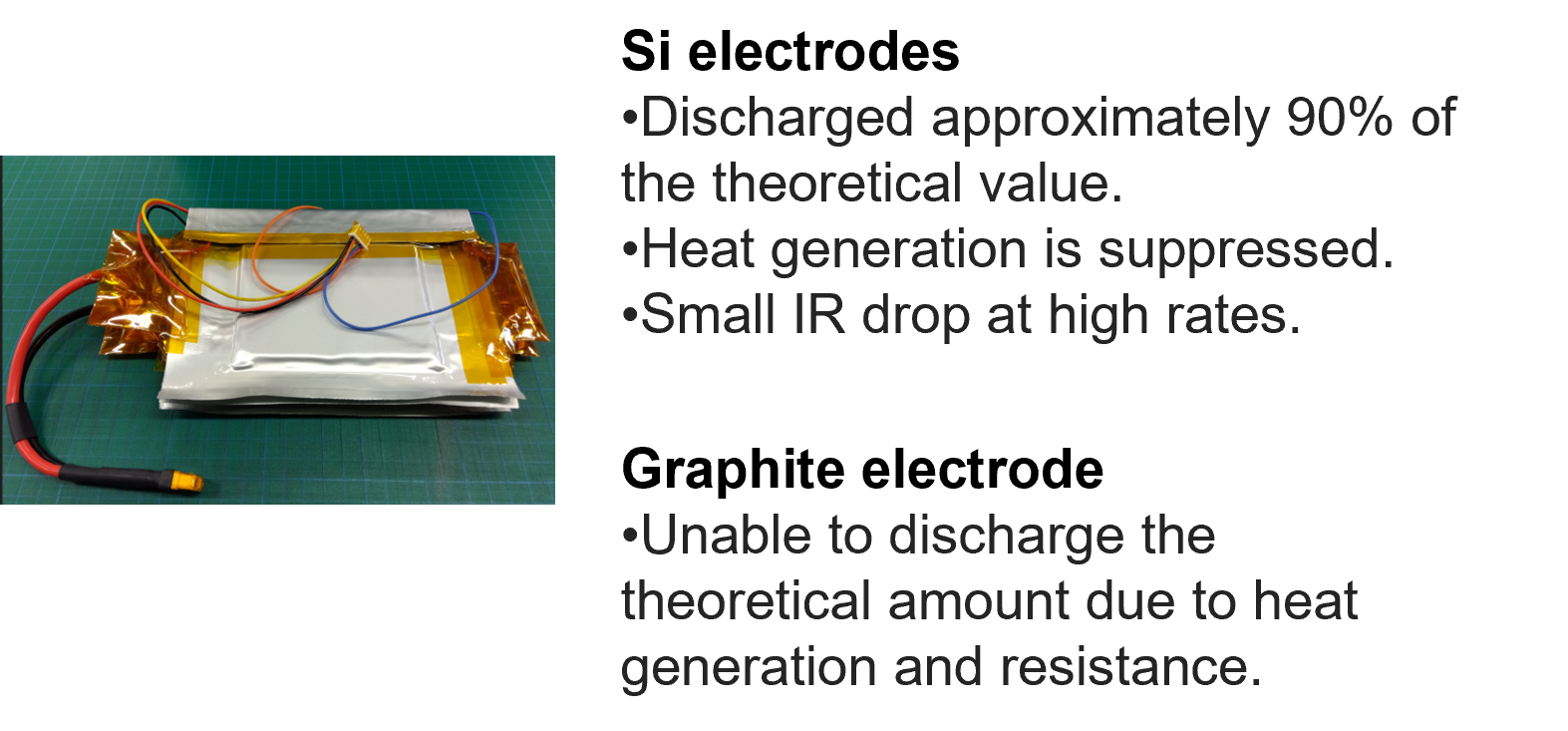

Silicon anode battery using polyimide binder vs. commercial graphite single battery

⇒ Confirmed the superiority of polyimide binder

【Discharge characteristics of Si electrodes】

【Discharge characteristics of Graphite electrodes】