Tyranno Fiber®

Outline

Developed using UBE's unique technology, Tyranno Fiber is a continuous ceramic fiber composed of silicon, metal (titanium, zirconium or aluminum), carbon, and oxygen.

Advanced composites reinforced by Tyranno Fiber are expected to play an important role in the environmental fields of the future, such as ultra high speed transportation, energy efficiency, CO2 and NOx reduction, and purification of exhaust fumes.

Reinforcement fibers for these applications require high temperature stability, high strength, and high reliability in extreme environments. Tyranno Fiber possesses excellent properties and is being utilized in many areas.

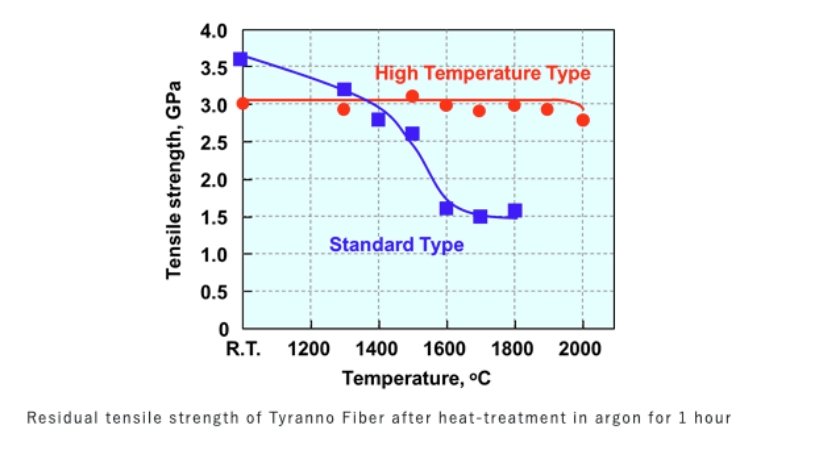

One of the great features of Tyranno Fiber is its high strength and high temperature stability. Especially, the polycrystalline Tyranno Fiber (High Temperature Type) has a heat resistance to at least 1,800℃ and offers a lot of potential as a material for reinforcing next-generation composite materials.

Properties of Tyranno Fiber

| Property Grade |

Standard Type ZMI |

High Temperature Type SA |

||

|---|---|---|---|---|

| Fiber diameter | (μm) | 11 | 10 | |

| Number of filaments | (fil./yarn) | 800 | 800 | |

| Tex | (g/1000m) | 200 | 175 | |

| Tensile strength | (GPa) | 3.4 | 3.2 | |

| Tensile modulus | (GPa) | 210 | 400 | |

| Elongation at break | (%) | 1.5 | 0.8 | |

| Density | (g/cm³) | 2.6 | 3.1 | |

| Contents | (wt.%) | Si | 56 | 68 |

| C | 34 | 31 | ||

| O | 9 | < 1 | ||

| Metal | 1 | < 2 | ||

| Thermal conductivity | (W/m K) | 2.5 | 45 | |

Secondary Products

Tyranno Fiber can be supplied in woven fabric (plain weave) etc.

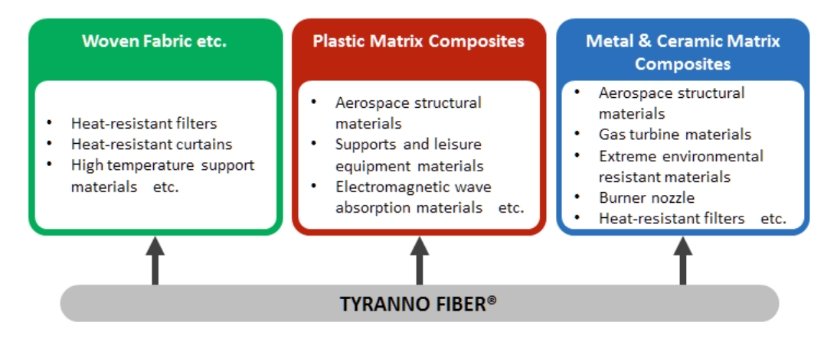

Tyranno Fiber Applications