High Purity Silicon Nitride Powder

Product Summary

UBE Silicon Nitride Powder is the high-quality ceramic material which is made by the original Imide-decomposition process.

This process, our proprietary process, has superiority in particle design with purity, morphology, crystal phase, grain size, its distribution and other important properties which can control the microstructure, and consequently it enhances thermomechanical properties required for final products such as strength, fracture toughness, hardness, thermal shock fracture resistance, thermal conductivity, etc.

Since 1986, its going on the market, UBE Silicon Nitride Powder has been used for various final applications in a wide range of industries such as automobile, aerospace, electronics and others, and recognized as a global standard by ceramic manufacturers all over the world.

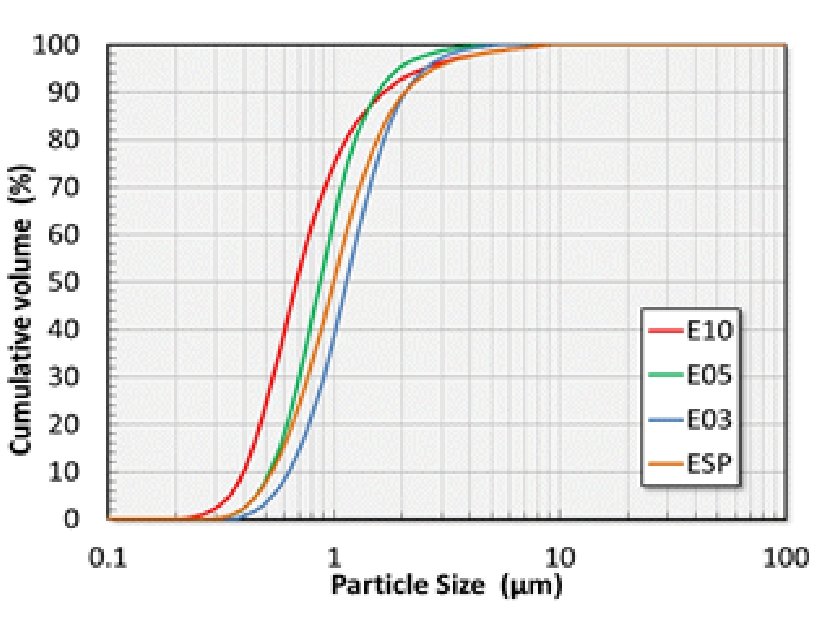

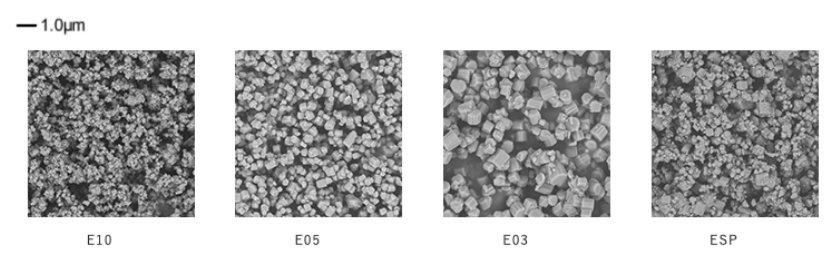

In addition to SN-E10, its flagship grade, UBE has SN-E05 and SN-E03 in its product lineup.

These grades differ in mainly particle size and distribution and fulfill the properties required for each application.

Product Line

| Type | Grade | SSA (m²/g) |

O (wt%) |

C* (wt%) |

Cl (ppm) |

Fe* (ppm) |

Ca* (ppm) |

Al* (ppm) |

α-phase content (wt%) |

|---|---|---|---|---|---|---|---|---|---|

| Standard Grade (E series) |

SN-E10 | 9~13 | < 2.0 | 0.1 | < 100 | 10 | < 1 | 1 | > 95 |

| SN-E05 | 4~6 | 10 | < 1 | 1 | |||||

| SN-E03 | 2~4 | 11 | < 1 | 1 |

* typical value

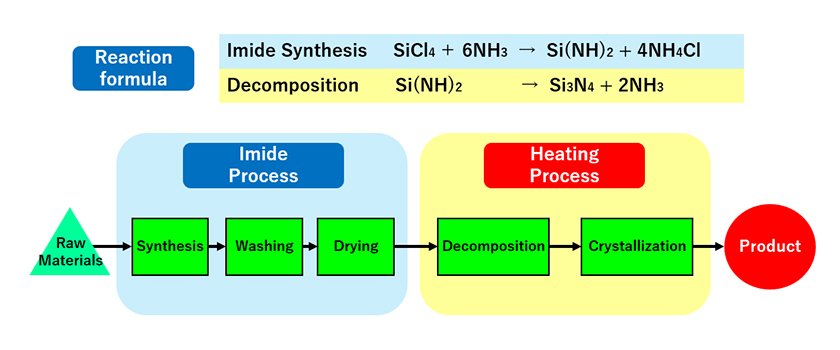

Manufacturing Process

Standard Grade

(E series)

Features

- High Purity

- Uniformity / Sharpness of particle size distribution

- High α-phase crystal content

Specifications

| Grade | SSA (m²/g) |

O (wt%) |

C* (wt%) |

Cl (ppm) |

Fe* (ppm) |

Ca* (ppm) |

Al* (ppm) |

α-phase content (wt%) |

|---|---|---|---|---|---|---|---|---|

| SN-E10 | 9~13 | < 2.0 | 0.1 | < 100 | 10 | < 1 | 1 | > 95 |

| SN-E05 | 4~6 | 10 | < 1 | 1 | ||||

| SN-E03 | 2~4 | 11 | < 1 | 1 |

* typical value

Particle Size Distribution

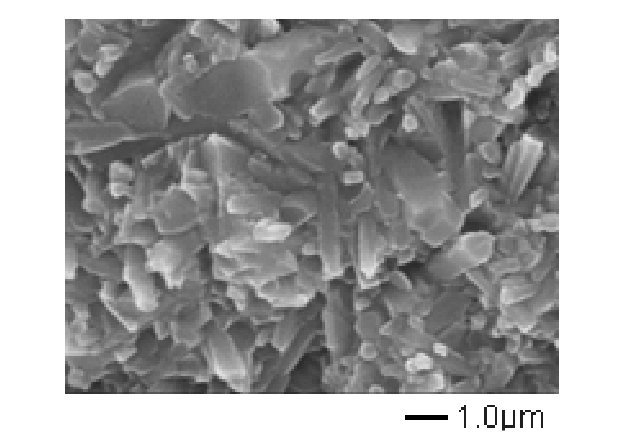

SEM Images

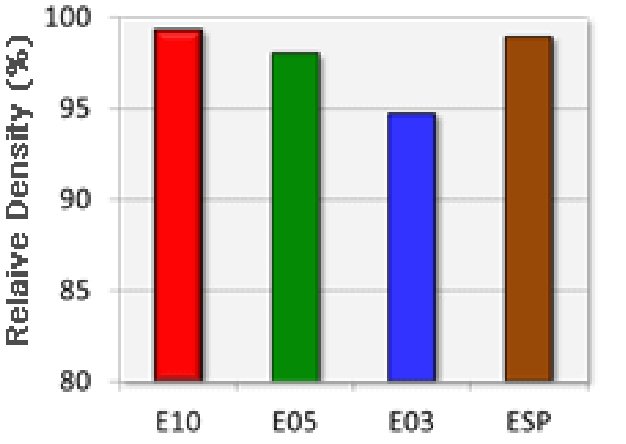

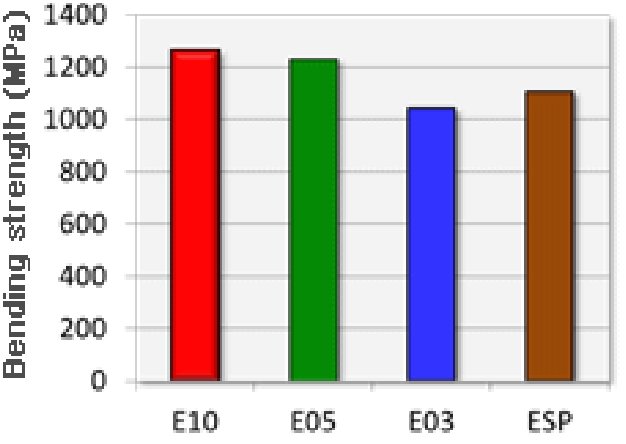

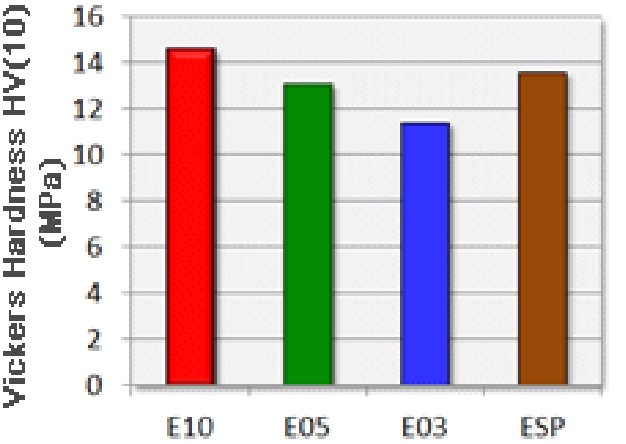

Mechanical Property (sintered)

Sintered Density

Bending Strength

Vickers Hardness

SEM Image of a section

of sintered SN-E10