RID-ACE

- Outline

- Basic Principle

- System Configuration

- Usage

- Design Specs

- Test Data

- Test Method

- Precautions

- Deodorizer Replacement

- System Dimensions and Weight

- Utilities

Outline

The odor that results when cleaning chambers is largely the result of toxic gases such as HCl, HF, and Cl2. It worsens the work environment and is a major obstacle to work efficiency. This unit reduces these cases to the threshold limit value (TLV) or lower, thereby improving work efficiency.

*RID-ACE is a registered trademark in Japan.

Basic Principle

- Solids adhering to the chamber's inner wall react with the moisture content in the air, producing toxic HCl and HF. There are also the residual gases used in etching.

- Air is introduced into the chamber, causing the solids (including ALCl3) to react with the air's moisture content. The resulting HCl, HF and other chemicals, as well as the residual gasses from etching, including Cl2, BCl3, and HBr, are removed by reacting with the deodorizer and being physically adsorbed.

- The replacement of a treatment agent is managed by the operation time of the blower.

Note:This device can only be used for gases for etching equipment. Flammable gases and other kinds of gases cannot be used.

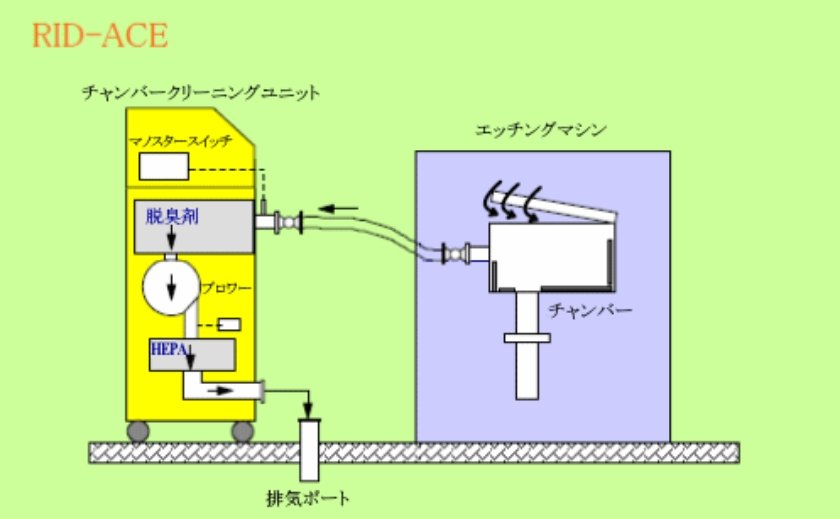

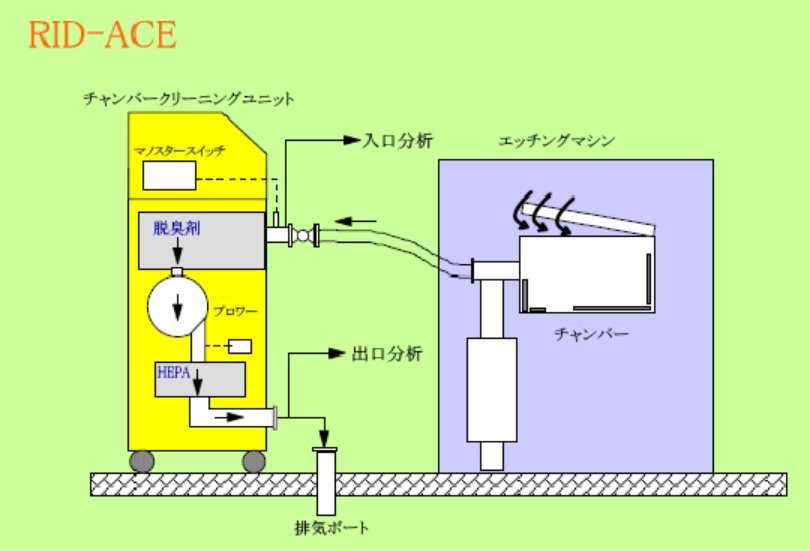

System Configuration

Usage

- Connect the system to the chamber using NW40 and then use the system blower to suction out the gases in the chamber.

- Toxic gas is removed by reacting with the deodorizer and being physically adsorbed.

- Fine dust is removed by a HEPA filter.

- Exhaust is either returned to the clean room or output through an exhaust duct.

- After this action is taken, cleaning the chamber will further reduce the odor.

Design Specs

| Exhaust capacity | Max1.1m³/min |

|---|---|

| Target gases |

|

| Target gas concentration | 500ppm or less |

| Exhaust gas concentration | TLVor less |

| Treatment agent replacement schedule | Replace after blower operates 300 hours (time function) |

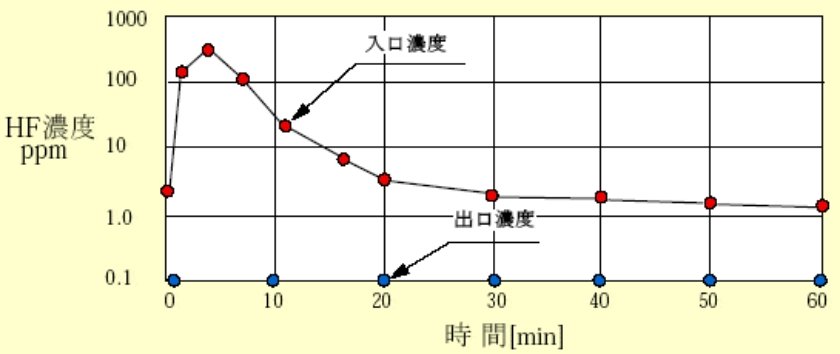

Test Data

| Suction rate | 1.1m³/min |

|---|---|

| Target system | LCD manufacturing process etching machine |

| Measurement method | Inlet gases: Gas detector tube HF No.17 Outlet gases: Tape-style HF gas monitor |

| Measurement result | Output gas concentration of 100ppb or less |

Test Method

Precautions

- 1.To avoid heat buildup, use the prescribed target gases only. Do not introduce other gases or any liquid.

- To avoid heat buildup and degraded performance, do not introduce gases above the prescribed concentrations.

Deodorizer Replacement

Return the adsorption column to the address shown below after 300 hours of use. The company will refill it with new deodorizer and send it back to you.

Ube Electronics, Ltd.

Omine-cho Mugigawa, Mine-shi, Yamaguchi 759-2214, Japan

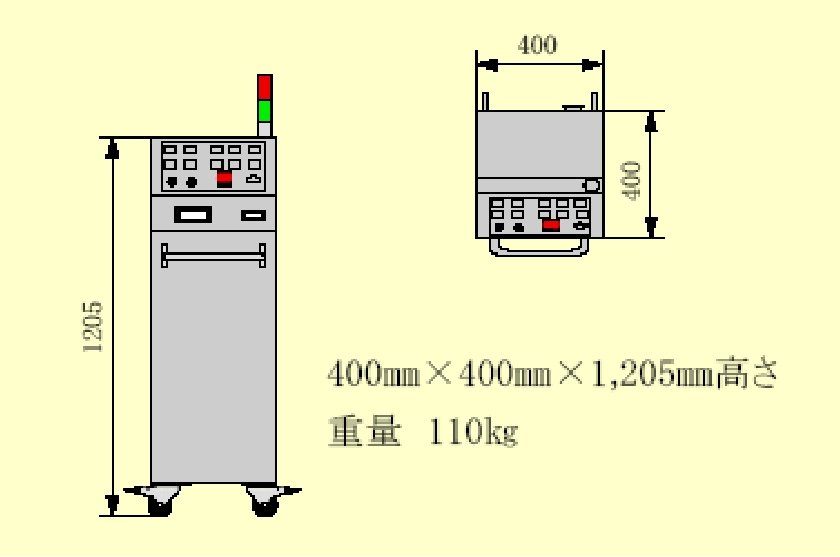

System Dimensions and Weight

Utilities

| Electricity | AC100V、50/60Hz、15A |

|---|---|

| Intake port | NW40 |

| Exhaust port | NW40 |