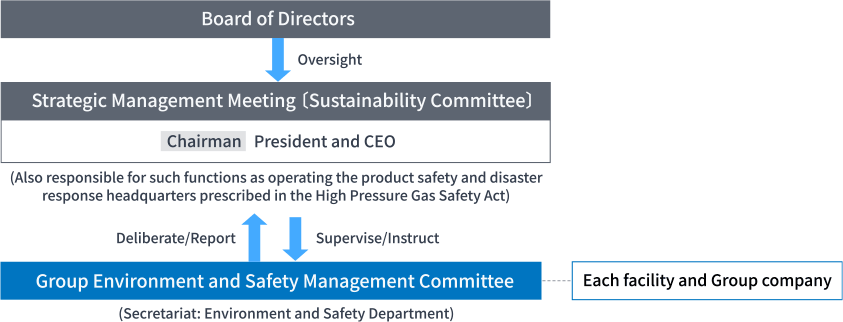

Policy and Basic Mindset

Basic Approach to Process Safety and Disaster Prevention Initiatives

The issue of “Safety and Security” is addressed by the UBE Management Principles, and the Company has announced that it will work to conserve the global environment and practice safe and secure manufacturing. To achieve Goal 2 as set out in the UBE Group Basic Policy on the Environment and Safety, “We will ensure the safety and security of facilities and maintain stable operations,” we strive to continue avoiding process accidents by developing worksite frameworks that prevent accidents and, to this end, ensures the thorough identification of risks and systematic implementation of far-reaching measures to counter those identified risks.