Policy and Basic Mindset

Basic Approach to Occupational Safety and Health Initiatives

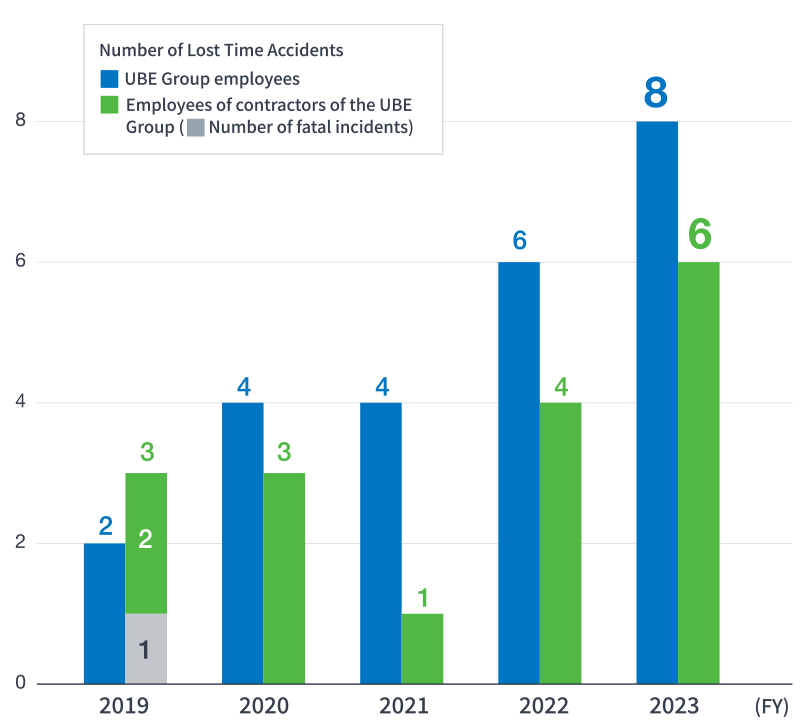

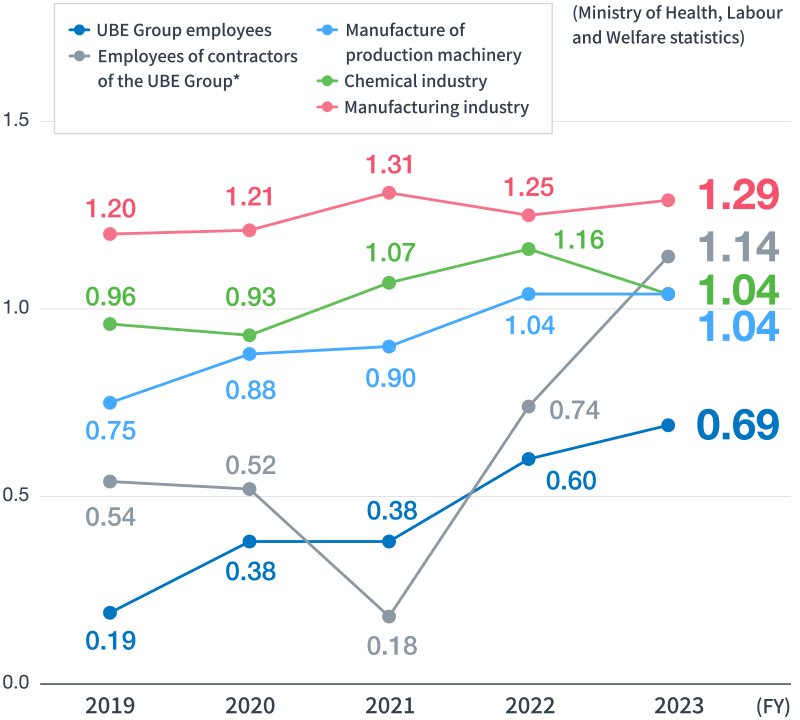

The UBE Group strives to continue preventing occupational accidents by making operations inherently safe. The Group’s efforts are designed to foster a safety-driven corporate culture and to reduce risks by enhancing safety initiatives and making continuous improvements. In the area of occupational health, each business site establishes an occupational safety and health management system to maintain and improve corporate activities. The UBE Group also endeavors to ensure the mental and physical health of employees by improving lifestyle habits through health checkups and follow-up care as well as various measures such as mental health consultations.