Policy and Basic Mindset

UBE Group Basic Policy for Circular Economy

The UBE Group will contribute to solving global environmental problems by focusing on Carbon Neutrality, Circular Economy, and Nature Positive (conservation and reconstruction of the natural environment).

Achieving Circular Economy means transforming the current linear material flow into a circular one, reusing waste and end-of-life products, and establishing an economic system that creates value.

Due to population growth and economic development, there is a growing concern about resource depletion and resource supply insecurity. Circulating limited resources supports the stability of social infrastructure.

The UBE Group will strive to realize Circular Economy.

Scope

This policy applies to the UBE Group (UBE Corporation and its consolidated subsidiaries) and covers the entire value chain.

Goal

Realizing Circular Economy

Commitment

- We will formulate strategies that enable us to minimize risks and maximize opportunities while securing compliance with international frameworks, laws, regulations, and other rules.

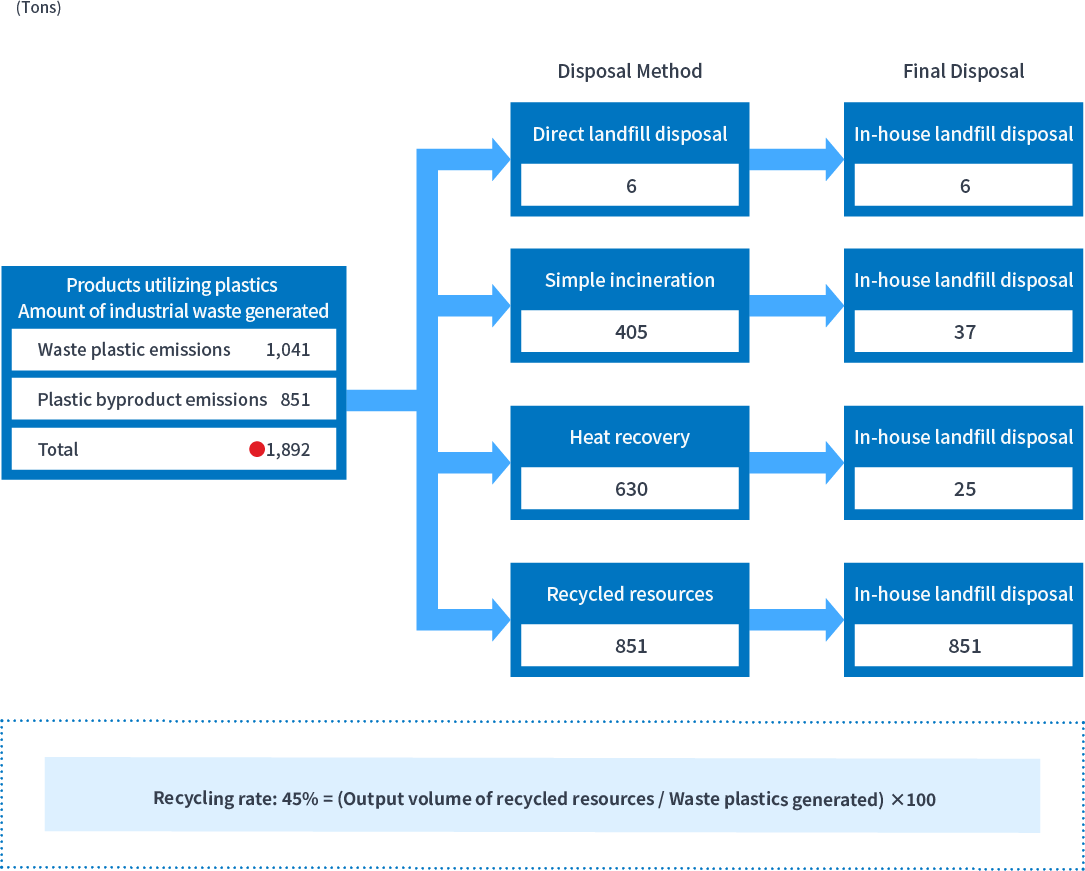

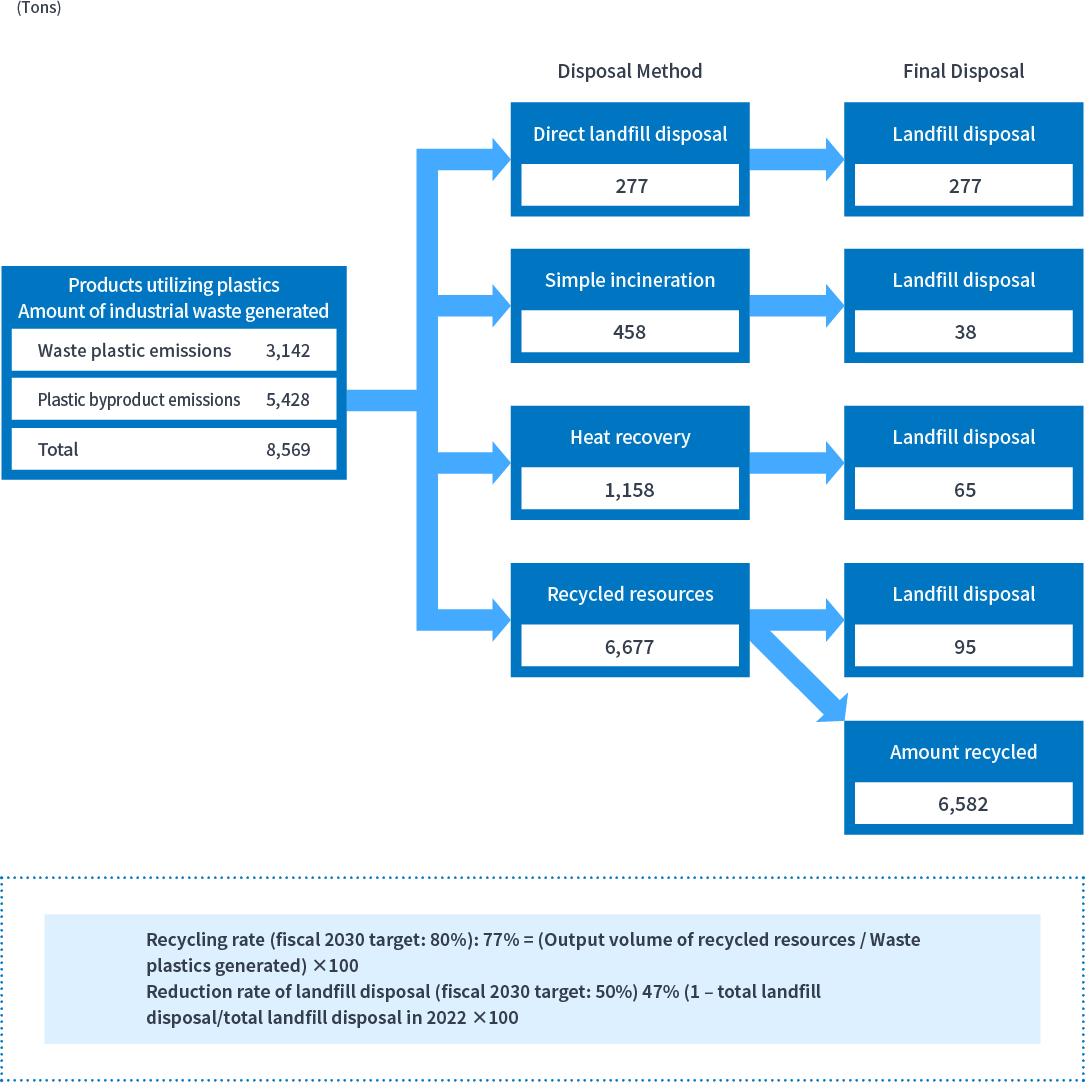

- We will reduce the volume of plastic and other waste emitted from each business base.

- We will promote our sustainable products designed to contribute to Circular Economy.

-

Fiscal 2030 targets regarding reductions in the volume of plastic and other waste emitted from each business base and the recycling of such waste:

- Reduction rate in the volume of waste disposed of via landfill: 50% or more (from fiscal 2022 levels)

- Plastic waste recycling rate: 80% or more

-

Fiscal 2030 target for the promotion of our sustainable products designed to contribute to Circular Economy:

- The weight-based sales volume of products contributing to Circular Economy: 50,000 tons or more

Responsible Departments and Review

The Sustainability Department is responsible for overseeing and managing this policy.

This Policy is subject to regular review at least once every year. Any revisions, whether as part of a scheduled review or required during the fiscal year, will be deliberated and approved by the Environmental Issues Committee.