Overview

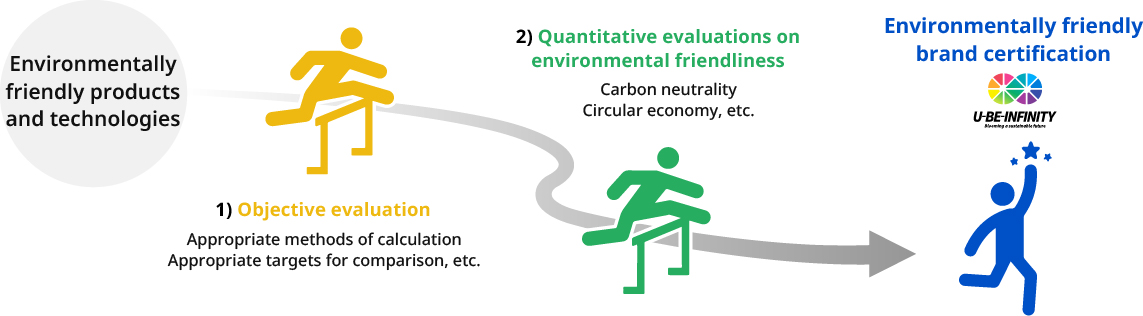

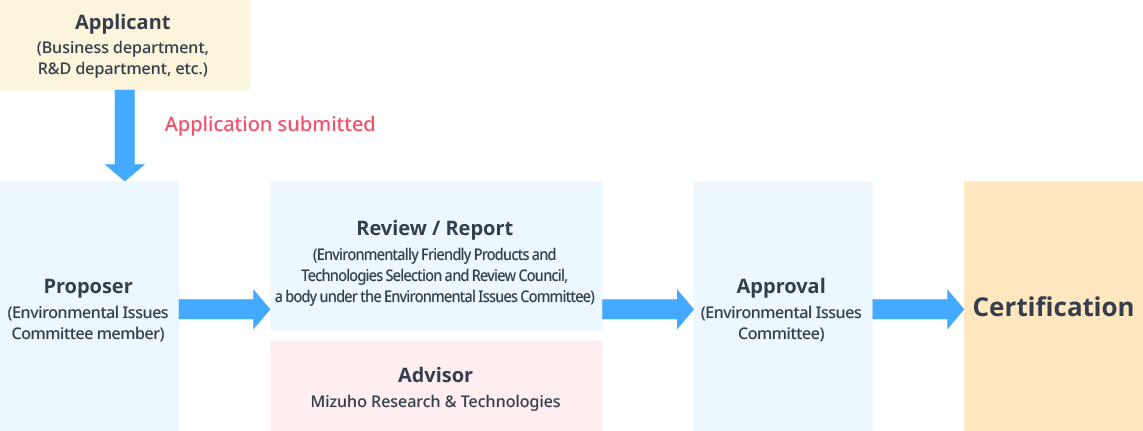

Products and technologies that eliminate or mitigate environmental burdens in the supply chain are evaluated by the UBE Group along the UBE Guidelines, which were formulated based on the 2015 revisions to ISO 14001. Products and technologies that meet these standards are recognized internally as environmentally friendly.

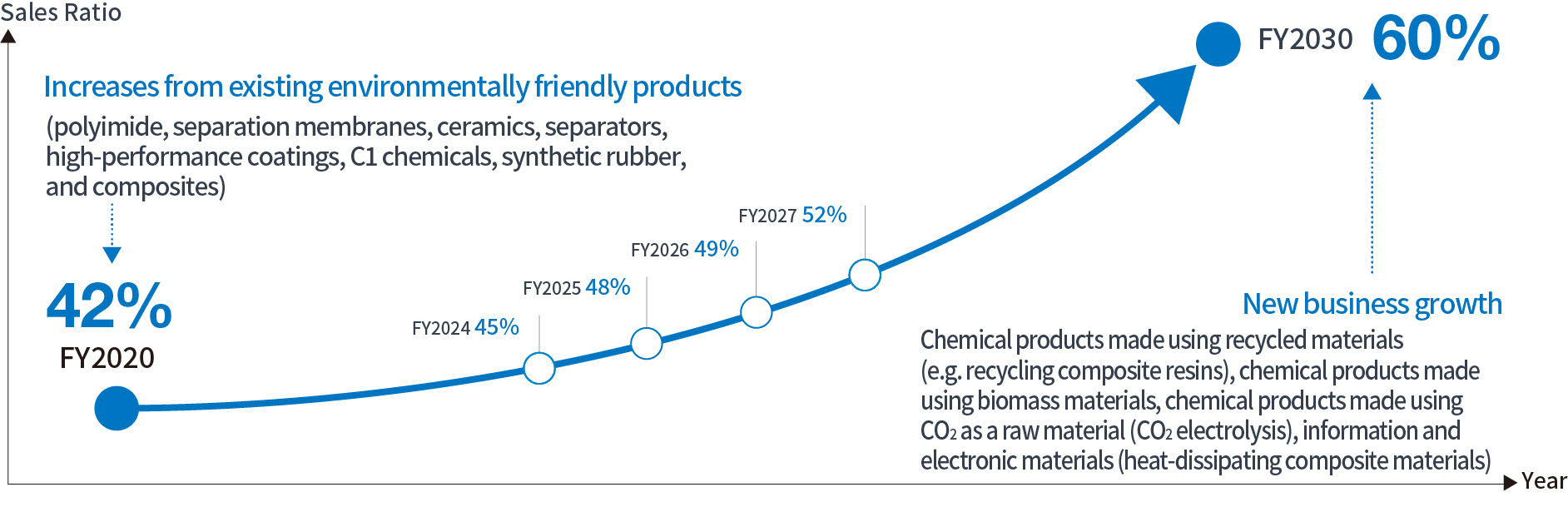

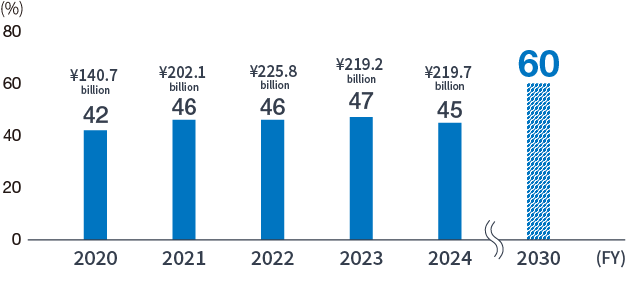

We promote the development of environmentally friendly products and technologies and strive to provide them to an ever greater number of customers in line with efforts to contribute to the carbon neutrality of the UBE Group as well as throughout society. To this end, we have set a target of having environmentally friendly products and technologies comprise 60% or more of our net sales by fiscal 2030.

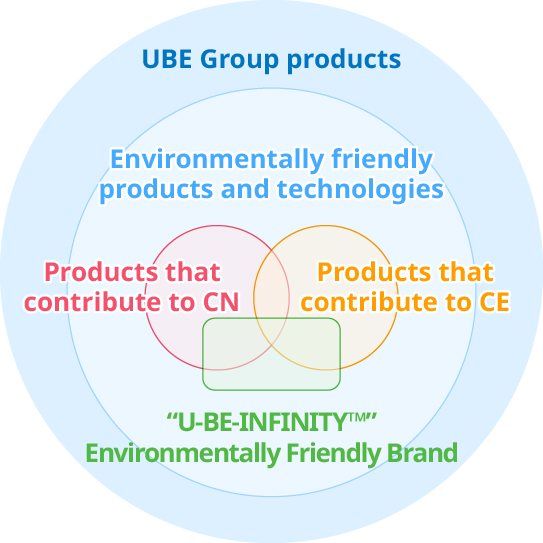

Products and technologies that contribute to carbon neutrality (CN) and a circular economy (CE) are included among our environmentally friendly offerings, and products with particularly exceptional capabilities are recognized under the environmentally friendly brand U-BE-INFINITY™.

-

Diagram of environmentally friendly products and technologies, products that contribute to CN and CE, and our environmentally friendly brand

-

Trends in the UBE Group’s consolidated net sales of environmentally friendly products and technologies*1

- *1Excluding cement-related business transferred to Mitsubishi UBE Cement Corporation.